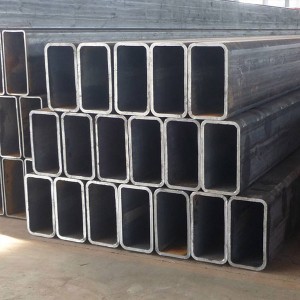

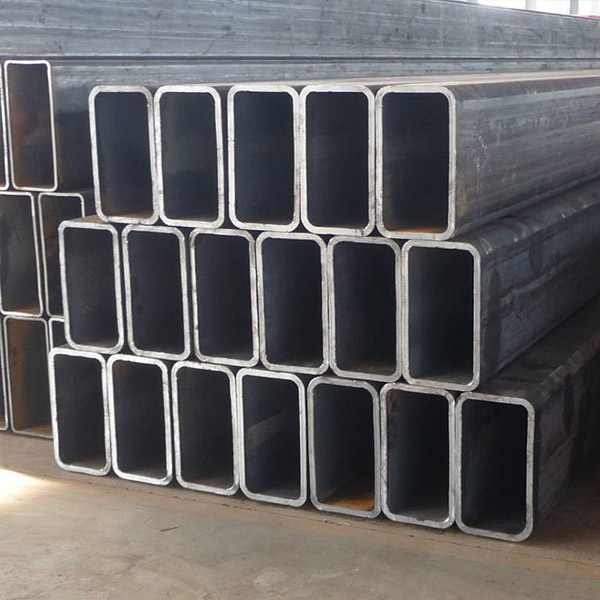

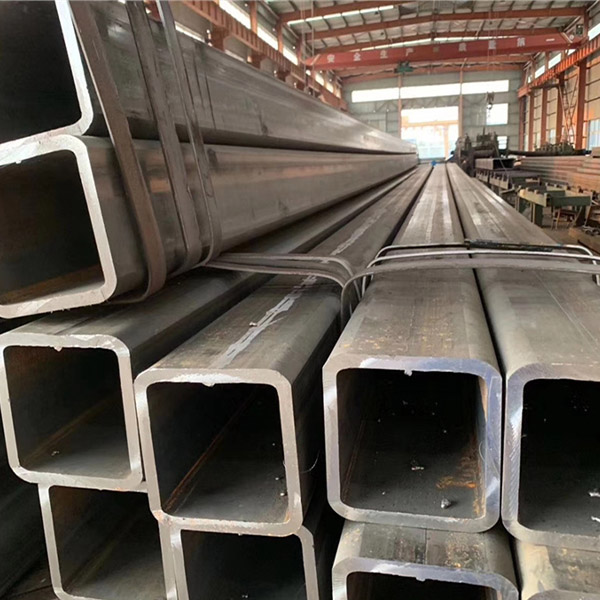

Welded Square Tube

made in China

Application: boiler tube,

Whether the pipeline is connected with alloy: non-alloy

Sectional shape: square

Special tube: API

Tube thickness: 1.5-60

Surface treatment: black paint

Tolerance: ±1%

Processing services: bending, welding, punching, cutting

Material: Q195/Q215/Q235/Q345/10#/20#

Surface: black spray paint

Shape: square tube

Packing: standard packing

Keywords: seamless steel pipe

Delivery time: 7-15 days

Inner shape steel pipe: black hollow section

Minimum order quantity: 1 ton

Purpose: Building structure

Technology: Hot Rolling

Authentication: API

1. Welded square tube is a hollow square section steel square tube, also known as hollow cold-formed steel. It is formed by cold bending and high-frequency welding after hot-rolled or cold-rolled strip or coil as the blank Shaped steel with square cross-sectional shape and size.

In addition to the thickening of the wall thickness of the thick-walled square tube, the corner size and edge flatness reach or exceed the level of the resistance welded cold-formed square tube. The size of the R angle is generally between 2 times and 3 times the wall thickness. .According to the needs of customers, we can also produce R-angle square tubes of the size required by customers;

2. Square tube Seamless square tube is a long steel strip with a hollow section and no joints on the periphery. It is a square tube formed by extruding a seamless tube through 4 sides of a mold. The square tube has a hollow section and is used in large quantities. It is used in liquid transportation, hydraulic support, mechanical structure, medium and low pressure, high pressure boiler tube, heat exchange tube, gas, petroleum and other industries. It is stronger than welded and will not crack.

1. Process flow of sanitary mirror tube:

Tube blank-inspection-peeling-inspection-heating-perforation-pickling-grinding-lubrication and air drying-welding head-cold drawing-solution treatment-pickling-pickling Passivation-inspection-cold rolling-degreasing-cutting-air drying-internal polishing-external polishing-inspection-marking-finished product packaging.

2. Industrial pipe process

Tube blank-inspection-peeling-inspection-heating-perforation-pickling-grinding-lubrication and air drying-welding head-cold drawing-solution treatment-pickling-pickling Passivation-inspection.

3. Process flow of welded pipe

Uncoiling-leveling-end shearing and welding-looper-forming-welding-inner and outer bead removal-pre-correction-induction heat treatment-sizing and straightening-eddy current testing-cutting ——Hydraulic pressure inspection——Pickling——Final inspection——Packing.

4. Seamless square tube process

Round steel-tube billet-inspection-heating-piercing-sizing-hot rolling-flat head-inspection-pickling-spherical annealing-cold drawing-forming-Qikou- -test

Q345A:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345B:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345C:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.030,Al≥0.015;

Q345D:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.025,Al≥0.015;

Q345E:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.025,S≤0.020,Al≥0.015;

Q345A, B, C, D, E Nb≤0.07,V≤0.15,Ti≤0.20,Cr≤0.30,N≤0.012,Mo≤0.10. 20#, Q235B

| Thick-walled square pipe specification table (mm) | Thick-walled rectangular pipe specification table (mm) | ||

| 16~34×0.4~2.0 | 380~500×380~500×8.0~30.0 | 10~20×20~40×0.6~12.0 | 250~300×100~250×6~30.0 |

| 16~34×0.4~2.0 | Another redraw specification is as follows | 20×50×1.0~2.0 | 400×250×8~30.0 |

| 38×38×1.0~4.0 | 550×550×10.0~40.0 | 22~40×35~100×0.9~5.0 | 400~×300×8~30.0 |

| 40~95×40~95×1.0~8.0 | 600~1000×600~1000×10.0~50.0 | 25×40×0.9~3.75 | 450~500×200~450×8~30.0 |

| 100×100×2.0~8.0 | 50×60×2.0~5.0 | Another redraw specification is as follows | |

| 120~350×120~350×4.0~30.0 | 50~200×60~150×2.0~12.0 | 600~1000×200~800×10~28.0 | |