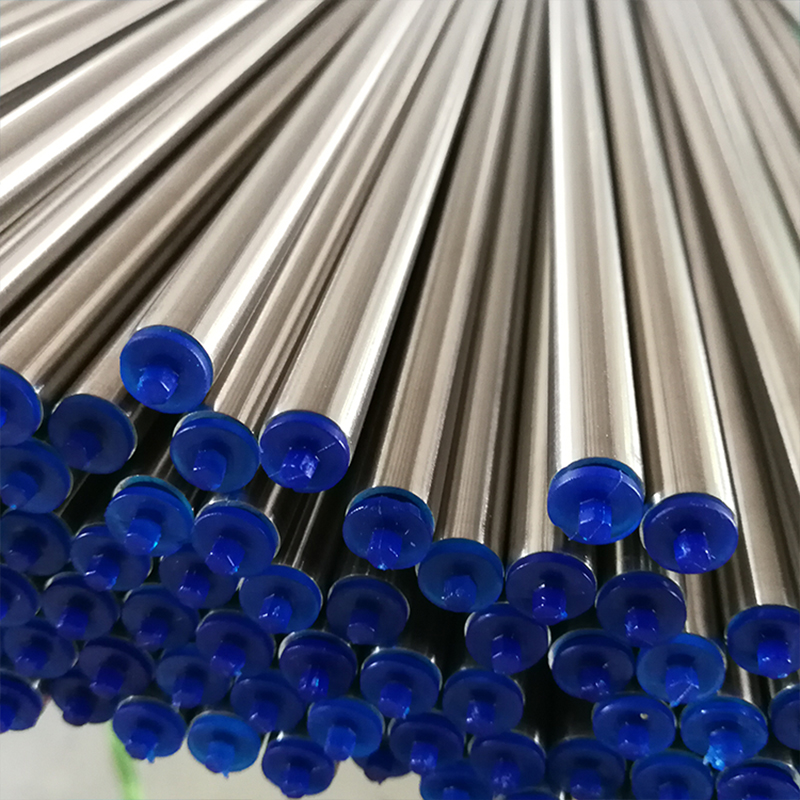

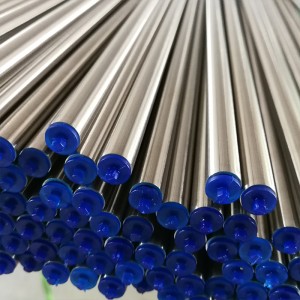

Stainless Steel Seamless Steel Pipe For Fluid Transportation

1. 321 stainless steel pipe. Seamless steel pipe (GB14976-2002) is used to manufacture superheated steam pipes, boiling water pipes and locomotive boiler superheated steam pipes, large smoke pipes, small smoke pipes and arch brick pipes of various structures. Carbon structural steel hot-rolled and cold-drawn (rolled) seamless steel tubes.

2. 321 stainless steel pipes: high-quality carbon structural steel, alloy structural steel and stainless heat-resistant steel seamless steel pipes mainly used to manufacture high-pressure and above steam boiler pipes. These boiler pipes are often under high temperature and high pressure. Work and pipes will also undergo oxidation and corrosion under the action of high-temperature flue gas and water vapor. Therefore, steel pipes are required to have high enduring strength, high oxidation resistance, and good organizational stability. Hydraulic prop pipes.

3. The steel grades used for 321 stainless steel pipes are: 304 321 316 317 310, etc.

4. Alloy structural steel pipe steel grades 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB, etc.; there are stainless heat-resistant steel commonly used 1Cr18Ni9, 1Cr18Ni11Nb high-pressure boiler tubes, in addition to ensuring chemical composition and mechanical properties, the water pressure should be done one by one. For the test, a flaring and flattening test should be performed.

5. 321 stainless steel pipes are delivered in heat-treated condition. In addition, there are also certain requirements for the microstructure, grain size, and decarburized layer of the finished steel pipe. Seamless steel pipes for geological drilling and oil drilling control; use drilling rigs to drill wells for the exploration of underground rock structure, groundwater, oil, natural gas and mineral resources. Petroleum and natural gas exploration is even more inseparable from well drilling. Seamless steel pipes for geological drilling and control are the main equipment for drilling, including core outer tubes, core inner tubes, casings, and drill pipes. Because the drilling pipe needs to be deep into the formation depth of several kilometers to work, 1cr5mo alloy pipe.

6. The working conditions are extremely complicated. The drill pipe is subjected to stresses such as tension, compression, bending, torsion, and uneven impact load, as well as mud and rock wear. Therefore, the pipe must have sufficient strength, hardness, wear resistance and Impact toughness, steel pipe used "DZ" (Geological Pinyin prefix) plus the number one to represent the yield point of steel, commonly used steel grades are 45MnB, 50Mn DZ45; DZ50 40Mn2, 40Mn2Si; DZ55 40Mn2Mo, 40MnVB; 40MnMoB of DZ60, 27MnMoVB of DZ65. The steel pipes are delivered in a heat-treated state.

7. Petroleum cracking pipes: seamless pipes for furnace pipes, heat exchanger pipes and pipelines used in petroleum refineries. Commonly used high-quality carbon steel (10, 20), alloy steel (12CrMo, 15CrMo), heat-resistant steel (12Cr2Mo, 15Cr5Mo), stainless steel (1Cr18Ni9, 1Cr18Ni9Ti) manufacturing.

8. Seamless steel pipes for 321 stainless steel pipes (GB3087-1999) are used to manufacture superheated steam pipes, boiling water pipes and locomotive boiler superheated steam pipes, large smoke pipes, small smoke pipes and arch brick pipes for various structures of low and medium pressure boilers. High-quality carbon structural steel hot-rolled and cold-drawn (rolled) seamless steel tubes. 321 stainless steel pipe: It is mainly used to manufacture high-quality carbon structural steel, alloy structural steel and stainless heat-resistant steel seamless steel pipes for steam boiler pipes of high pressure and above. These boiler pipes work under high temperature and high pressure. , The pipe will be oxidized and corroded under the action of high temperature flue gas and water vapor. Therefore, the steel pipe is required to have high enduring strength, high oxidation resistance, and good organization stability, hydraulic prop pipe.

9. 321 stainless steel pipes are delivered in heat-treated condition. In addition, there are also certain requirements for the microstructure, grain size, and decarburized layer of the finished steel pipe. Seamless steel pipes for geological drilling and oil drilling control; use drilling rigs to drill wells for the exploration of underground rock structure, groundwater, oil, natural gas and mineral resources.