Stainless Steel Hexagonal Steel

Standards: AiSi, ASTM, DIN, EN, GB, JIS

Grade: 300 series

Place of Origin: Shandong, China

Brand Name: Jinbaicheng

Type: Hexagonal

Application: Industry

Shape: Hexagonal

Special purpose: valve steel

Size: 0.5-508

Certification: Major product name:

Stainless steel hexagonal steel

Surface: polished

Material: 200 series 300 series 400 series

Technology: Cold Rolling

Length: customer request

Finish: Speak Polish

Item: Stainless Steel Bar

Minimum order quantity: 1 ton

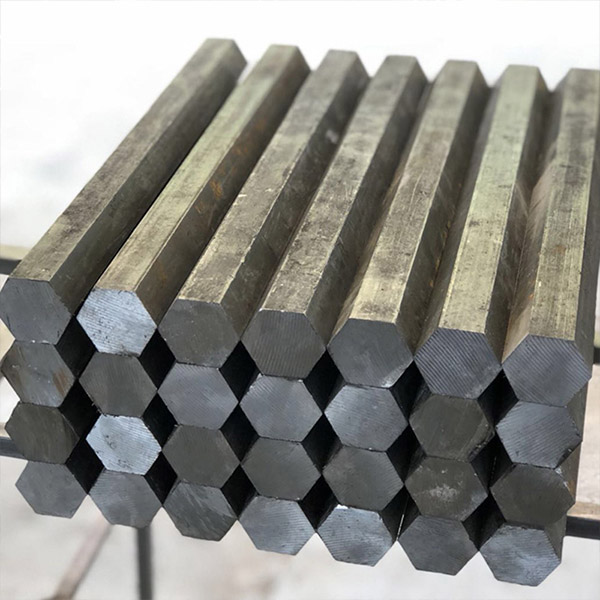

The special-shaped pipes are generally distinguished according to the cross section and the overall shape. They can be generally divided into: oval shaped steel pipes, triangular shaped steel pipes, hexagonal shaped steel pipes, diamond shaped steel pipes, stainless steel patterned pipes, stainless steel U-shaped steel pipes, and D-shaped pipes. Pipes, stainless steel elbows, S-shaped pipe elbows, octagonal shaped steel pipes, semi-circular shaped steel rounds, unequal-sided hexagonal shaped steel pipes, five-petal plum shaped shaped steel pipes, double convex shaped steel pipes, double concave shaped steel Stainless steel water trap, melon seed shaped steel pipe, conical shaped steel pipe, corrugated shaped steel pipe.

Hollow hexagonal steel is widely used in various structural parts, tools and mechanical parts. Compared with round pipes, hexagonal pipes generally have larger moments of inertia and section modulus, and have greater bending and torsion resistance, which can greatly reduce structural weight and save steel.

Hexagonal tubes are also divided into carbon steel hexagonal tubes, hexagonal oxygen blowing tubes, and stainless steel hexagonal tubes according to different processes and materials.

Hexagonal steel can be used to form various stress-bearing components according to the different needs of the structure, and can also be used as a connection between components. Widely used in various building structures and engineering structures, such as building beams, bridges, power transmission towers, lifting and transporting machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves, etc.

|

Opposite side distance S mm |

Allowable deviation, mm |

Cross-sectional area A, cm2 |

Theoretical weight, kg/m |

Opposite side distance S mm |

Allowable deviation, mm |

Cross-sectional area A, cm2 |

Theoretical weight, kg/m |

||||||||

|

Group 1 |

Group 2 |

Group 3 |

Hexagonal steel |

Octagonal steel |

Hexagonal steel |

Octagonal steel |

Group 1 |

Group 2 |

Group 3 |

Hexagonal steel |

Octagonal steel |

Hexagonal steel |

Octagonal steel |

||

|

8 |

±0.25 |

±0.35 |

±0.40 |

0.544 3 |

- |

0.435 |

- |

8 |

±0.25 |

±0.35 |

±0.40 |

0.544 3 |

- |

0.435 |

- |

|

9 |

0.701 5 |

- |

0.551 |

- |

9 |

0.701 5 |

- |

0.551 |

- |

||||||

|

10 |

0.866 |

- |

0.680 |

- |

10 |

0.866 |

- |

0.680 |

- |

||||||

|

11 |

1.048 |

- |

0.823 |

- |

11 |

1.048 |

- |

0.823 |

- |

||||||

|

12 |

1.247 |

- |

0.979 |

- |

12 |

1.247 |

- |

0.979 |

- |

||||||

|

13 |

1.464 |

- |

1.15 |

- |

13 |

1.464 |

- |

1.15 |

- |

||||||

|

14 |

1.697 |

- |

1.33 |

- |

14 |

1.697 |

- |

1.33 |

- |

||||||

|

15 |

1.949 |

- |

1.53 |

- |

15 |

1.949 |

- |

1.53 |

- |

||||||

|

16 |

2.217 |

2.120 |

1.74 |

1.66 |

16 |

2.217 |

2.120 |

1.74 |

1.66 |

||||||

|

17 |

2.503 |

- |

1.96 |

- |

17 |

2.503 |

- |

1.96 |

- |

||||||

|

18 |

2.808 |

2.683 |

2.20 |

2.16 |

18 |

2.808 |

2.683 |

2.20 |

2.16 |

||||||

|

19 |

3.126 |

- |

2.45 |

- |

19 |

3.126 |

- |

2.45 |

- |

||||||

|

20 |

3.464 |

3.312 |

2.72 |

2.60 |

20 |

3.464 |

3.312 |

2.72 |

2.60 |

||||||

|

21 |

±0.30 |

±0.40 |

±0.50 |

3.819 |

- |

3.00 |

|

21 |

±0.30 |

±0.40 |

±0.50 |

3.819 |

- |

3.00 |

|

|

22 |

4.192 |

4.088 |

3.29 |

3.15 |

22 |

4.192 |

4.088 |

3.29 |

3.15 |

||||||

|

23 |

4.581 |

- |

3.60 |

- |

23 |

4.581 |

- |

3.60 |

- |

||||||

|

24 |

4.988 |

- |

3.92 |

- |

24 |

4.988 |

- |

3.92 |

- |

||||||

|

25 |

5.413 |

5.175 |

4.25 |

4.06 |

25 |

5.413 |

5.175 |

4.25 |

4.06 |

||||||

|

26 |

5.854 |

- |

4.60 |

- |

26 |

5.854 |

- |

4.60 |

- |

||||||

|

27 |

6.314 |

- |

4.96 |

- |

27 |

6.314 |

- |

4.96 |

- |

||||||

|

28 |

6.790 |

6.492 |

5.33 |

5.10 |

28 |

6.790 |

6.492 |

5.33 |

5.10 |

||||||

|

30 |

7.794 |

7.452 |

6.12 |

5.85 |

30 |

7.794 |

7.452 |

6.12 |

5.85 |

||||||

|

32 |

±0.40 |

±0.50 |

±0.60 |

8.868 |

8.479 |

6.96 |

6.66 |

32 |

±0.40 |

±0.50 |

±0.60 |

8.868 |

8.479 |

6.96 |

6.66 |

|

34 |

10.011 |

9.572 |

7.86 |

7.51 |

34 |

10.011 |

9.572 |

7.86 |

7.51 |

||||||

|

36 |

11.223 |

10.731 |

8.81 |

8.42 |

36 |

11.223 |

10.731 |

8.81 |

8.42 |

||||||

|

38 |

12.505 |

11.956 |

9.82 |

9.39 |

38 |

12.505 |

11.956 |

9.82 |

9.39 |

||||||

|

40 |

13.86 |

13.25 |

10.88 |

10.40 |

40 |

13.86 |

13.25 |

10.88 |

10.40 |

||||||

|

42 |

15.28 |

- |

11.99 |

- |

42 |

15.28 |

- |

11.99 |

- |

||||||

|

45 |

17.54 |

- |

13.77 |

- |

45 |

17.54 |

- |

13.77 |

- |

||||||

|

48 |

19.95 |

- |

15.66 |

- |

48 |

19.95 |

- |

15.66 |

- |

||||||

|

50 |

21.65 |

- |

17.00 |

- |

50 |

21.65 |

- |

17.00 |

- |

||||||

|

53 |

±0.60 |

±0.70 |

±0.80 |

24.33 |

- |

19.10 |

- |

53 |

±0.60 |

±0.70 |

±0.80 |

24.33 |

- |

19.10 |

- |

|

56 |

27.16 |

- |

21.32 |

- |

56 |

27.16 |

- |

21.32 |

- |

||||||

|

58 |

29.13 |

- |

22.87 |

- |

58 |

29.13 |

- |

22.87 |

- |

||||||

|

60 |

31.18 |

- |

24.50 |

- |

60 |

31.18 |

- |

24.50 |

- |

||||||

|

63 |

34.37 |

- |

26.98 |

- |

63 |

34.37 |

- |

26.98 |

- |

||||||

|

65 |

36.59 |

- |

28.72 |

- |

65 |

36.59 |

- |

28.72 |

- |

||||||

|

68 |

40.04 |

- |

31.43 |

- |

68 |

40.04 |

- |

31.43 |

- |

||||||

|

70 |

42.53 |

- |

33.30 |

- |

70 |

42.53 |

- |

33.30 |

- |

||||||