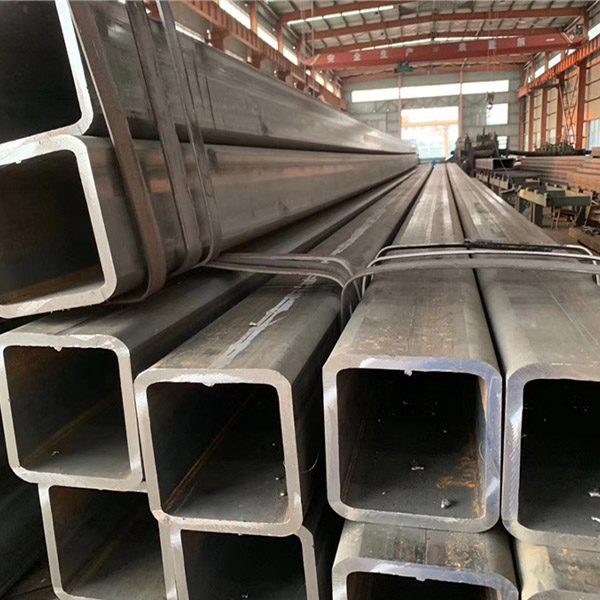

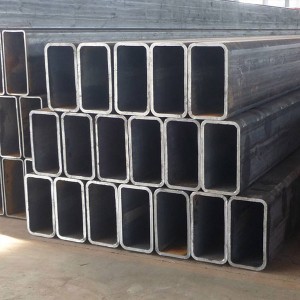

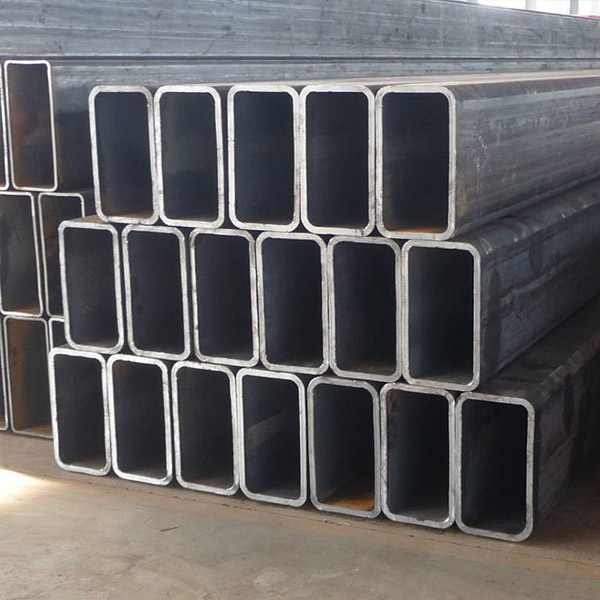

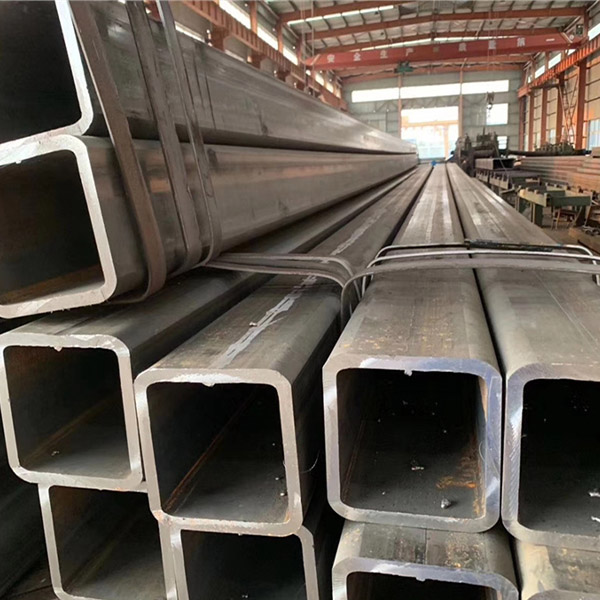

Seamless Square Tube

Application: fluid tube, boiler tube, structural tube

Alloyed or not: Non-alloyed

Sectional shape: square

Special tube: thick-walled tube

Thickness: 140

Standard: ASTM

Length: 12M, 6m, 6.4M, 1-12m

Certificate: ISO9001

Grade: Carbon Steel

Surface treatment: hot rolled

Tolerance: ±1%

Processing services: welding, punching, cutting, bending

Keyword: hot rolled tube

Minimum order quantity: 1 ton

Purpose: Building structure

Shape: square.

Rectangle. Round

Color: natural color

Packing: airworthiness standard

Packaging process: accept customized production

Depends on size: customized size

Supply Ability: 15,000 tons/ton of square steel pipes per month

Packing details: standard shipping packing or according to customer's requirements.

Port: China

Compared with solid steel such as round steel, steel pipe is generally lighter when the bending and torsion strength is the same. It is a kind of economical cross-section steel, which is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, Bicycle racks and steel scaffolding used in construction. The use of steel pipes to manufacture ring-shaped parts can increase the utilization rate of materials, simplify the manufacturing process, and save materials and processing man-hours, such as rolling bearing rings, jack sleeves, etc. It has been manufactured with steel pipes in 2013. Steel pipes are also an indispensable material for various conventional weapons and military machinery. Gun barrels and barrels are all made of steel pipes. Steel pipes can be divided into round pipes and special-shaped pipes according to their cross-sectional area shapes. Due to the condition of equal circumference, more fluid can be transported with a round tube. When the ring section is subjected to internal or external radial pressure, the force is relatively uniform, and most of the steel pipes are round pipes

1. Plasticity

Plasticity refers to the ability of metal materials to produce plastic deformation (permanent deformation) without being damaged under load.

2. Hardness

Hardness is a measure of the hardness of metal materials. The most commonly used method for measuring hardness in this production is the indentation hardness method, which uses a certain geometric indenter to press into the surface of the metal material to be tested under a certain load, and the hardness value is determined according to the degree of indentation.

Commonly used methods include Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV).

3. Fatigue

Strength, plasticity, and hardness are all indicators of the mechanical properties of metals under static load. In fact, many machine parts are working under cyclic loads, under this condition the parts will fatigue. Special-shaped steel pipes with other cross-sectional shapes are also required.

Welded steel pipe for low pressure fluid transportation (GB/T3092-1993) is also called general welded pipe, commonly known as clarinet. It is a welded steel pipe used for conveying water, gas, air, oil and heating steam and other generally lower pressure fluids and other purposes. The wall thickness of steel pipes is divided into ordinary steel pipes and thickened steel pipes; the connection end forms are divided into non-threaded steel pipes (smooth pipes) and threaded steel pipes. The specification of the steel pipe is expressed by the nominal diameter (mm), which is the approximate value of the inner diameter. It is customary to express in inches, such as 11/2. Welded steel pipes for low-pressure fluid transportation are not only directly used for fluid transportation, but also used as the original pipes of galvanized welded steel pipes for low-pressure fluid transportation.

Galvanized welded steel pipe for low pressure fluid transportation (GB/T3091-1993) is also called galvanized welded steel pipe, commonly known as white pipe. It is a hot-dip galvanized welded (furnace welded or electric welded) steel pipe used for conveying water, gas, air oil, heating steam, warm water and other generally lower pressure fluids or other purposes. The wall thickness of the steel pipe is divided into ordinary galvanized steel pipe and thick galvanized steel pipe; the connection end type is divided into non-threaded galvanized steel pipe and threaded galvanized steel pipe.

Ordinary carbon steel wire casing (GB3640-88) is a steel pipe used to protect wires in electrical installation projects such as industrial and civil construction and installation of machinery and equipment.

Straight seam electric welded steel pipe (YB242-63) is a steel pipe whose weld seam is parallel to the longitudinal direction of the steel pipe. Usually divided into metric electric welded steel pipe, electric welded thin-walled pipe, transformer cooling oil pipe and so on.

Spiral seam submerged arc welded steel pipe (SY5036-83) for pressure-bearing fluid transportation is a hot-rolled steel strip as a tube blank, which is spirally formed at regular temperature and welded by double-sided submerged arc welding. It is used for the spiral seam of pressure-bearing fluid transportation. Steel Pipe. The steel pipe has strong pressure-bearing capacity and good welding performance. After various strict scientific inspections and tests, it is safe and reliable to use. The steel pipe has a large diameter, high transmission efficiency, and can save investment in laying pipelines. Mainly used in pipelines for transporting oil and natural gas.

| Processing service | Bending, welding, uncoiling |

| Oiled or unoiled | No fuel |

| Product name | Inner coated plastic pipe |

| Moq | 1 ton |

| Key words | Lined with stainless steel pipe |

| Surface | Customer request |

| Shape | Square tube |

| Delivery time | Within 7-15 days |

| Standard | Gb 5310-1995 |

Galvanized steel pipe connection method: threaded, welded.

Roll groove connection

(1) Cracking of roll groove weld

1. Smooth the inner wall welding ribs of the pressure groove part of the nozzle to reduce the resistance of the rolling groove.

2, Adjust the axis of the steel pipe and the rolling grooving equipment, and require the steel pipe and the rolling grooving equipment to be level.

3. Adjust the groove pressing speed, and the groove forming time can not exceed the stipulation, apply force evenly and slowly.

(2) Roll groove steel pipe fracture

1. Smooth the inner wall welding ribs of the pressure groove part of the pipe mouth to reduce the resistance of the rolling groove.

2, Adjust the axis of the steel pipe and the rolling grooving equipment, requiring the steel pipe and the rolling grooving equipment to be level.

3. Adjust the pressing speed, the pressing speed cannot exceed the stipulation, apply force evenly and slowly.

4. Check the width and model of the support roller and pressure roller of the rolling groove equipment, and check whether there is a mismatch in the size of the two rollers, which may cause seizure.

5. Use a vernier caliper to check whether the groove of the steel pipe is specified.

(3) The groove formed by the rolling groove machine should meet the following requirements

1, The surface of the pipe end to the groove section should be smooth and free of unevenness and roll marks.

2, The center of the groove should be concentric with the pipe wall, the width and depth of the groove should meet the requirements, and check whether the clamp part type is correct.

3. Apply lubricant on the rubber sealing ring and check whether the rubber sealing ring is damaged. The lubricant must not be oil lubricant.

Welded connection

1. The pipe mouth of the galvanized steel pipe is not in a straight line and there is a problem with the oblique mouth of the steel pipe after butting. It is recommended to cut off the pipe head for a short period of time before processing.

2, After the galvanized steel pipe nozzles are connected, the two nozzles are not tightly connected, resulting in uneven thickness of the welded joint; and the pipe is elliptical due to its own reasons or transportation bumps. It is recommended to cut off the pipe head for a short period of time. Process again.

3. After the nozzles of galvanized steel pipes are butted, blisters appear at the nozzles:

4. Due to technical reasons during welding.

5. There are zinc nodules in the nozzle, which can cause welding difficulties and blisters. If the zinc nodules are too large and too many pipes, simple zinc nodules should be removed.

Wire connection

1, Threaded buckle: The pipe hoop and the threaded buckle can not be completely contacted, loosen, cut off the random buckle part, and re-install the thread.

2. The steel pipe thread and the pipe hoop thread do not match and cannot be connected. The pipe hoop should be replaced or the equipment should be adjusted and re-threaded.

3. Missing print after the steel pipe is threaded: Measure whether the wall thickness of the steel pipe can meet the standard thickness requirements of the threaded pipe