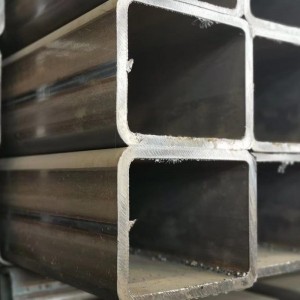

Pre-Galvanized Square/Rectangular Tube

1. 16mn Continental Square Tube

Chemical composition: carbon C: 0.17 ~ 0.24 "silicon Si: 0.17 ~ 0.37 manganese Mn: 0.35 ~ 0.65 sulfur S: ≤ 0.035 phosphorus P: ≤ 0.035 chromium Cr: ≤ 0.25 nickel Ni: ≤ 0.

2. 16mn square tube

Chemical composition: carbon C: 0.17 ~ 0.24 "silicon Si: 0.17 ~ 0.37 manganese Mn: 0.35 ~ 0.65 sulfur S: ≤ 0.035 phosphorus P: ≤ 0.035 chromium Cr: ≤ 0.25 nickel Ni: ≤ 0.25 copper Cu: ≤ 0.25

1.1 Plasticity

Plasticity is the ability of a metallic material to produce plastic deformation (permanent deformation) under load without damage.

1.2 Hardness

Hardness is a pointer to the degree of hardness or softness of a metallic material. The most commonly used method for determining hardness in production is the indentation hardness method, which uses an indenter of a certain geometry to press into the surface of the tested metal material under a certain load and determines its hardness value according to the degree of being pressed into it.

Commonly used methods are Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV) methods.

1.3 Fatigue

The strength, plasticity and hardness discussed earlier are all pointers to the mechanical properties of the metal under static load. In fact, many machine parts work under cyclic loads, and under such conditions the parts produce fatigue.

1.4 Impact toughness

The load acting on the machine part at a large speed is called impact load, and the ability of the metal to resist damage under impact load is called impact toughness.

1.5 Strength

Strength is the resistance of a metal material to damage (excessive plastic deformation or fracture) under a static load. As the load action in the form of tensile, compression, bending, shear, so the strength is also divided into tensile strength, compressive strength, bending strength, shear strength, etc.. There is often a certain connection between the various strengths, the use of the general tensile strength as the most basic strength pointer.

Square tube is used in construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation support, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, boiler construction, highway railings, housing construction, pressure vessels, petroleum storage tanks, bridges, power station equipment, lifting and transportation machinery and other high load welded structural parts, etc.

Process classification

Square tube is classified according to production process: hot rolled seamless square tube, cold drawn seamless square tube, extruded seamless square tube, welded square tube.

Among them, welded square tube is divided into

1. according to the process - arc welding square tube, resistance welding square tube (high frequency, low frequency), gas welding square tube, furnace welding square tube

2. according to the welding seam - straight seam welded square pipe, spiral welded square pipe.

Material classification

Square pipe by material: plain carbon steel square pipe, low alloy square pipe.

1. Plain carbon steel is divided into: Q195, Q215, Q235, SS400, 20# steel, 45# steel, etc.

2. Low alloy steel is divided into: Q345, 16Mn, Q390, ST52-3, etc.

Production standard classification

Square tube according to production standards: national standard square tube, Japanese standard square tube, imperial square tube, American standard square tube, European standard square tube, non-standard square tube.

Section shape classification

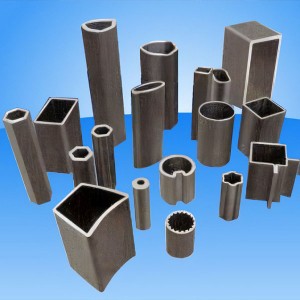

Square tube according to the shape of the section classification.

1. Simple section square tube: square square tube, rectangular square tube.

2. Complex section square tube: flower square tube, open square tube, corrugated square tube, shaped square tube.

Surface treatment classification

Square tube according to surface treatment: hot dip galvanized square tube, electro galvanized square tube, oiled square tube, pickled square tube.

Use classification

Square tube by application: decorative square tube, machine tool equipment square tube, machinery industry square tube, chemical industry square tube, steel structure square tube, shipbuilding square tube, automotive square tube, steel beam square tube, special purpose square tube.

Wall thickness classification

Square tube is classified by wall thickness: super thick wall square tube, thick wall square tube and thin wall square tube.

| Thick-walled square tube specification table (mm) | Thick-walled rectangular pipe specification table (mm) | ||

| 16~34×0.4~2.0 | 380~500×380~500×8.0~30.0 | 10~20×20~40×0.6~12.0 | 250~300×100~250×6~30.0 |

| 35×35×1.0~4.0 | Another re-drawing specifications are as follows | 20×50×1.0~2.0 | 400×250×8~30.0 |

| 38×38×1.0~4.0 | 550×550×10.0~40.0 | 22~40×35~100×0.9~5.0 | 400~×300×8~30.0 |

| 40~95×40~95×1.0~8.0 | 600~1000×600~1000×10.0~50.0 | 25×40×0.9~3.75 | 450~500×200~450×8~30.0 |

| 100×100×2.0~8.0 | 50×60×2.0~5.0 | Another re-drawing specifications are as follows | |

| 120~350×120~350×4.0~30.0 | 50~200×60~150×2.0~12.0 | 600~1000×200~800×10~28.0 | |