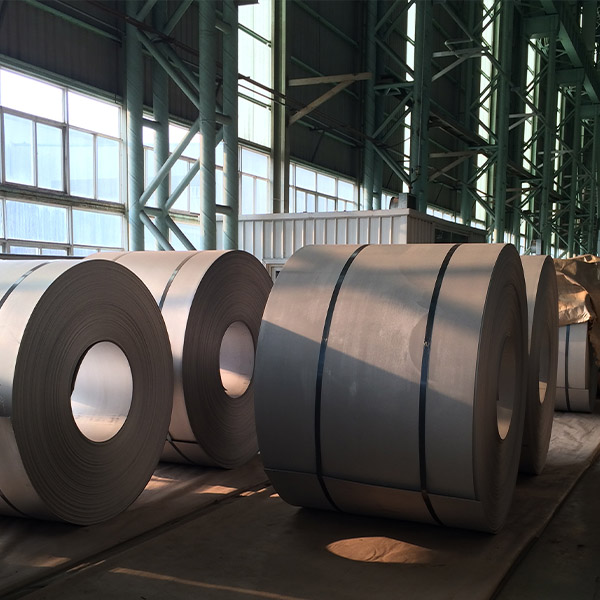

Pickling Hot Rolled Steel Coil

The size of the steel plate should meet the requirements of the table "Dimensions and Specifications of Hot Rolled Steel Plates (Excerpted from GB/T709-1988)".

The size of the steel strip should meet the requirements of the table "Dimensions and Specifications of Hot Rolled Steel Strip (Excerpted from GB/T709-1988)".

The width of the steel plate can also be any size of 50mm or a multiple of 10mm.

The length of the steel plate is any size of 100mm or a multiple of 50mm, but the minimum length of the steel plate with a width less than or equal to 4mm shall not be less than 1.2m, and the minimum length of a steel plate with a thickness greater than 4mm shall not be less than 2m.

According to the requirements, the thickness of steel plate less than 30mm, the thickness interval can be 0.5mm.

According to needs, after negotiation between the supplier and the buyer, steel plates and strips of other sizes can be supplied.

Common thickness: 0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.35, 2.45, 2.50, 2.70, 2.75, 2.8, 2.9, 2.95, 3.0, 3.25, 3.3, 3.5, 3.75, 3.8, 3.9, 3.95, 4, 4.25 , 4.5, 4.7, 4.75, 5, 5.5, 5.75, 6, 6.75, 7, 7.5, 7.75, 8, 8.75, 9, 9.5, 9.75, 10, 10.5, 11, 11.5, 12

Hot continuous rolling can be divided into ordinary carbon structural steel, low alloy steel, and alloy steel according to its material and performance. According to their different uses, they can be divided into: cold forming steel, structural steel, automotive structural steel, corrosion-resistant structural steel, mechanical structural steel, welded gas cylinder and pressure vessel steel, pipeline steel, etc.

The hot-dip galvanized hot-rolled plate unit adopts an improved Sendzimir annealing process, and the raw material is hot-rolled pickled coils. The production process is as follows:

Hot-rolled pickled coil → uncoiling → cutting head and tail → welding → entrance looper → modified Sendzimir horizontal annealing furnace → hot-dip galvanizing → cooling after plating → zinc layer thickness gauge → smoothing and straightening → passivation treatment → Inspection table → Electrostatic oiling → Coiling → Weighing and packing → Finished product storage.