News

-

Unleashing the Potential: Exploring the Features and Applications of Zirconium Plate

Introduction: Zirconium plates are at the forefront of the materials industry, offering unparalleled advantages and versatile applications. In this blog, we will delve into the features of zirconium plates, their various grades, and explore the vast scope of applications they offer. Paragr...Read more -

Exploring the Applications and Characteristics of Titanium Plate

Introduce: Titanium metal plates are widely popular because of their remarkable features such as light weight, high strength, corrosion resistance, and good biocompatibility. In this blog, we will delve into the applications of titanium plates and highlight the similarities and differences betwee...Read more -

Essential Methods to Enhancing the Longevity and Anti-Corrosion Performance of Hot-Dip Galvanized Steel Strip

Introduction: Welcome to Shandong Jinbaicheng Metal Materials Co., Ltd – a leading metal factory in China with over 15 years of experience in exporting high-quality hot-dip galvanized steel strips and coils. In this blog, we will discuss the crucial methods to prolong the life of hot-dip ga...Read more -

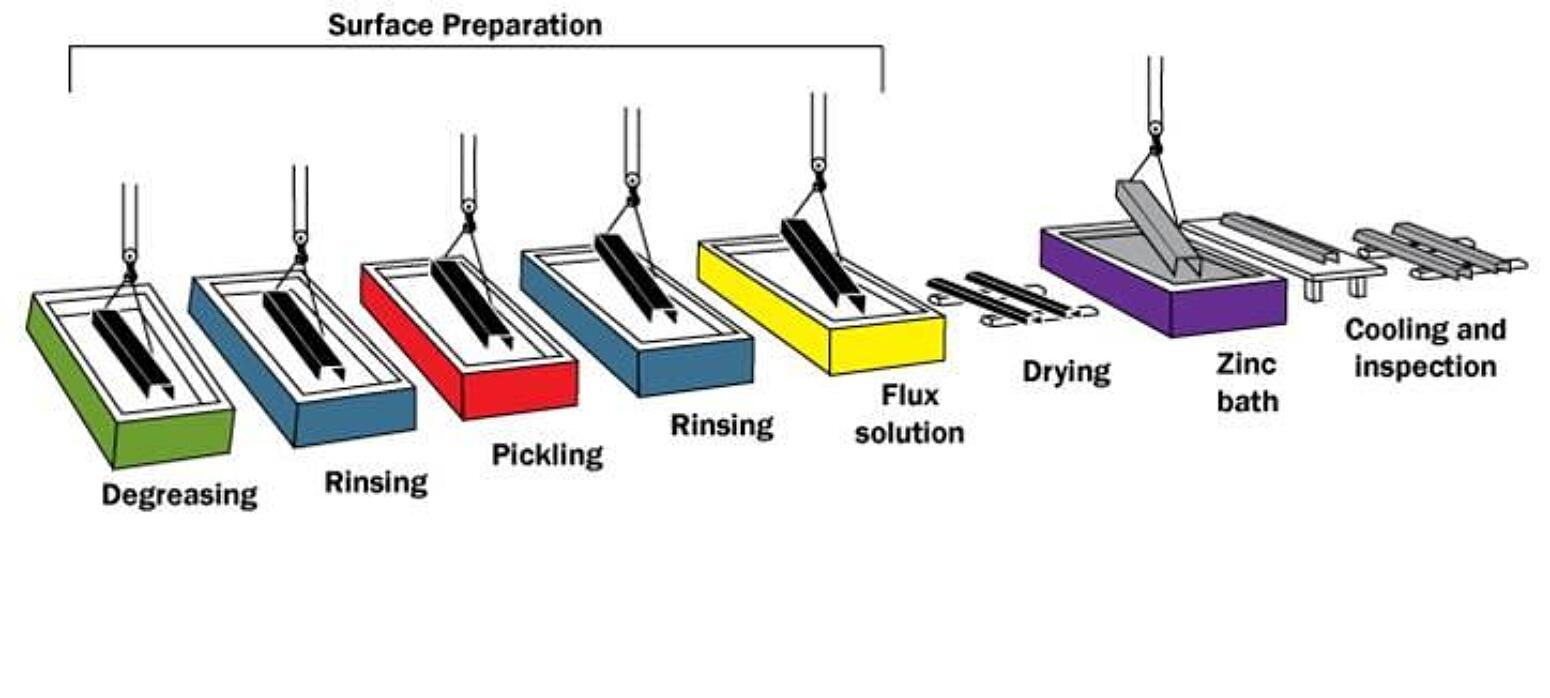

Do you know the manufacturing process of hot-dip galvanized steel strip?

This article will discuss the manufacturing process of hot-dip galvanized steel strip, the advantages and disadvantages of this material, commonly used steel grades, and highlight the characteristics that make it a popular choice in construction, home furnishing, transportation and other industri...Read more -

Demystifying the strength of ASTM A500 square pipe

Introduce: Welcome to our blog! In today’s article, we will discuss the American Standard ASTM A500 Square Pipe and its significance in the steel export industry. As a leading ASTM A500 standard steel pipe producer and supplier, Shandong Jinbaicheng Metal Materials Co., Ltd. is committed to...Read more -

AISI 1040 Carbon Steel: A Versatile Durable Material for Industrial Applications

Introduce: AISI 1040 Carbon Steel, also known as UNS G10400, is a widely used steel alloy known for its high carbon content. This material exhibits excellent mechanical properties, making it suitable for various industrial applications. In this article, we will discuss the properties, application...Read more -

Advantages of straight seam steel pipes and components

Introduce: Shandong Jinbaicheng Metal Materials Co., Ltd. is a leading producer of straight seam steel pipes and steel components. With highly advanced manufacturing process and expertise in delivering quality products, the company has established itself as a reliable supplier in the industry. In...Read more -

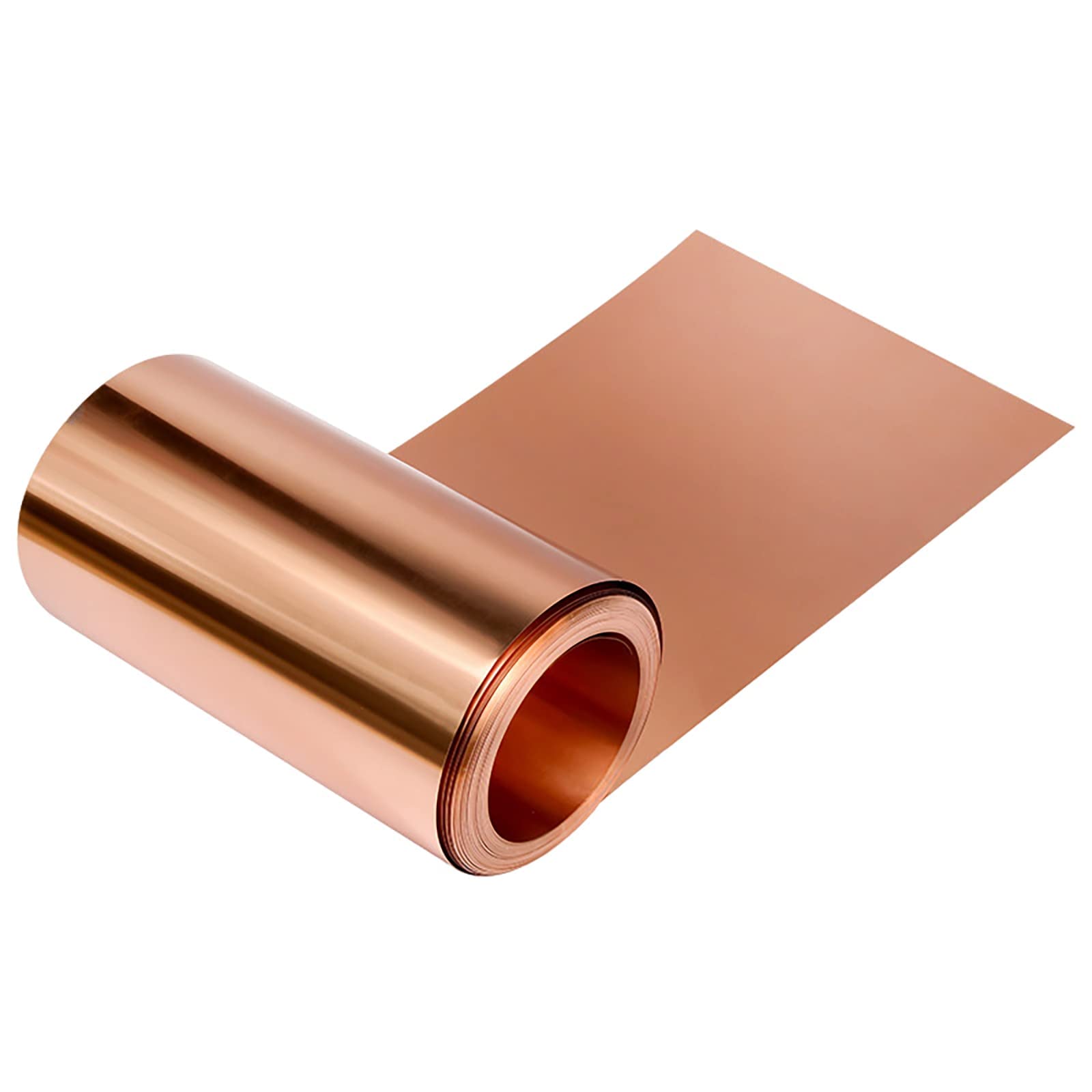

Advantages of copper foil and how to choose the right grade

Introduce of copper foil: Copper foil is a flexible and versatile material with numerous applications across a variety of industries. Known for its excellent electrical conductivity and corrosion resistance, it is highly sought after in electronics, transformers and decorative uses. Shandong Jinb...Read more -

What is weathering steel

Introduction to weathering steel materials Weathering steel, that is, atmospheric corrosion resistant steel, is a low alloy steel series between ordinary steel and stainless steel. weathering steel is made of ordinary carbon steel with a small amount of corrosion resistant elements such as copper...Read more -

What Is The Difference Between Tool Steel And Stainless Steel?

Although they are both steel alloys, stainless steel and tool steel differ from each other in composition, price, durability, properties, and application, etc. Here are the differences between these two types of steel. Tool Steel vs. Stainless Steel: Properties Both stainless steel and tool ste...Read more -

What is Stainless Steel Rebar?

Although the use of carbon steel rebar is sufficient in many construction projects, in some cases, concrete cannot provide sufficient natural protection. This is particularly true for marine environments and environments where deicing agents are used, which can lead to chloride induced corrosion....Read more -

The common surface processes of aluminum alloys

Commonly used metal materials include stainless steel, aluminum alloy, pure aluminum profiles, zinc alloy, brass, etc. This article mainly focuses on aluminum and its alloys, introducing several common surface treatment processes used on them. Aluminum and its alloys have the characteristics of e...Read more