Manufacturing Companies for Brass Rod - Galvanized Steel Coil – JINBAICHENG

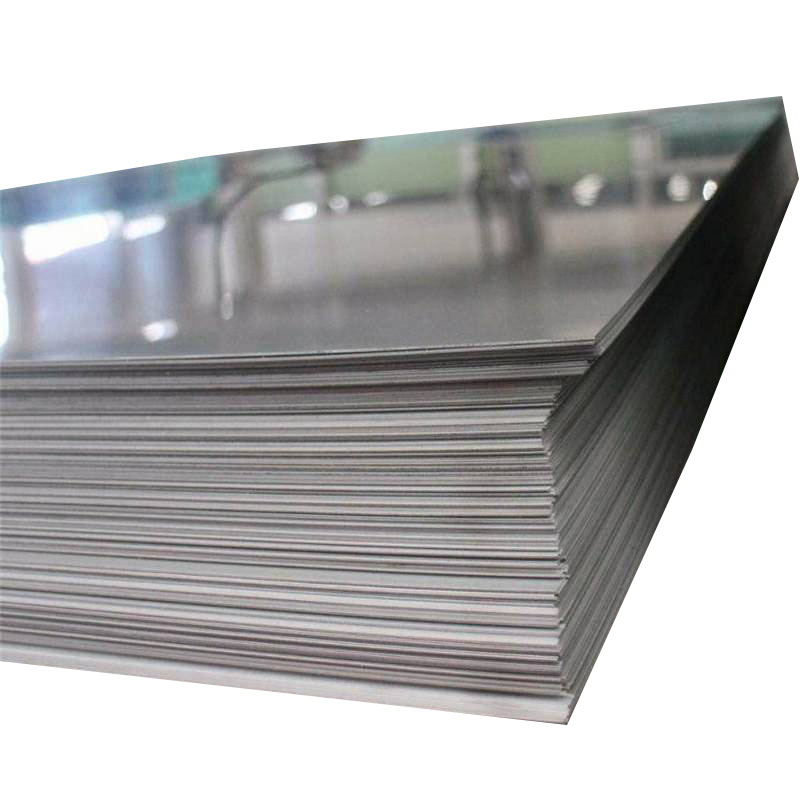

Manufacturing Companies for Brass Rod - Galvanized Steel Coil – JINBAICHENG Detail:

Product Introduction

Standards: ACE, ASTM, BS, DIN, GB, JIS

Grade: G550

Origin: Shandong, China

Brand name: jinbaicheng

Model: 0.12-4.0mm * 600-1250mm

Type: steel coil, cold rolled steel plate

Technology: Cold Rolling

Surface treatment: aluminum zinc plating

Application: structure, roof, building construction

Special purpose: high strength steel plate

Width: 600-1250mm

Length: customer requirements

Tolerance: ± 5%

Processing services: uncoiling and cutting

Product Name: high quality G550 Aluzinc coated AZ 150 GL aluminum zinc plated steel coil

Surface: coating, chromizing, oiling, anti fingerprint

Sequins: Small / normal / large

Aluminum zinc coating: 30g-150g / m2

Certificate: ISO 9001

Price terms: FOB CIF CFR

Payment term: LCD

Delivery time: 15 days after payment

Minimum order quantity: 25 tons

Packing: standard seaworthy packing

Product Display

General purpose

01. Mechanical occlusion; 02. The weight code of the zinc layer shall not exceed Z350 Stamping; 03. The thickness range is ≥0.4mm, the weight of the zinc layer does not exceed Z275 Deep drawing; 04. Special killed steel deep drawing; 05. Non-aging super deep drawing; 06. Structure 220, 250, 280, 320, 350, 400, 450, 550 Thickness <0.4mm steel plate is not suitable for 220, 250, 280 and 320 grades.

Passivation treatment of the galvanized layer can reduce folding rust (white rust) under moisture storage and transportation conditions. However, the anti-corrosion performance of this chemical treatment is limited, and it hinders the adhesion of most coatings. This kind of treatment is generally not used on the zinc-iron alloy coating. In addition to the smooth surface, as a rule, the manufacturer will passivate other types of zinc coatings.

Through phosphating treatment, galvanized steel sheets of various coating types can be coated without further treatment except for normal cleaning. This treatment can improve the adhesion and corrosion resistance of the coating, and reduce the risk of corrosion during storage and transportation. After phosphating, it can be used with a suitable lubricant to improve the molding performance.

Scope of application

Automobile industry

Hot-rolled pickled oil-coated sheet is a new type of steel required by the automotive industry. Its better surface quality, thickness tolerance, and processing performance can replace body panels and auto parts produced by cold-rolled sheets in the past, thereby reducing raw materials The cost is about 10%. With the development of the economy, the production of automobiles has also increased significantly, and the use of plates has continued to increase. The original design of many vehicle models in the domestic automobile industry requires the use of hot-rolled pickled plates, such as: car subframes, wheel spokes, front and rear Due to the insufficient supply of domestic hot-rolled pickling plates for bridge assemblies, truck box plates, protective nets, automobile beams and spare parts, automobile factories generally use cold plates or hot plates instead or pick them by themselves.

Machinery Industry

Hot-rolled pickled plates are mainly used in textile machinery, mining machinery, fans and some general machinery. Such as the manufacture of compressor housings and upper and lower covers for household refrigerators and air conditioners, pressure vessels and mufflers for power compressors, and bases for screw air compressors. Among them, household refrigerators and air-conditioning compressors use the most pickling plates, and the deep drawing performance of the pickling plates is relatively high. The materials are mainly SPHC, SPHD, SPHE, SAPH370, the thickness range is 1.0-4.5mm, and the required specifications are 2.0-3.5mm. According to relevant data, in the first half of this year, refrigerator compressors and air-conditioning compressors required hot-rolled pickling plates of 80,000 tons and 135,000 tons, respectively. The fan industry now mainly uses cold-rolled plates and hot-rolled plates. Hot-rolled pickled plates can be used instead of cold plates to manufacture impellers, shells, flanges, mufflers, bases, platforms, etc., of blowers and ventilators.

Other industry

Other industry applications mainly include bicycle parts, various welded pipes, electrical cabinets, highway guardrails, supermarket shelves, warehouse shelves, fences, water heater tanks, barrels, iron ladders, and various shapes of stamping parts. With the continuous development of the economy, zero-part processing is spreading across all industries, and processing plants have sprung up rapidly. The demand for plates has greatly increased, and the potential demand for hot-rolled pickled plates has also increased.

Main advantage

Pickling plate is made of high-quality hot-rolled sheet as raw material. After the pickling unit removes the oxide layer, trims and finishes, the surface quality and use requirements (mainly cold-formed or stamping performance) are between hot-rolled and cold-rolled The intermediate product between the plates is an ideal substitute for some hot-rolled plates and cold-rolled plates. Compared with hot-rolled plates, the main advantages of pickled plates are: 1. Good surface quality. Because the hot-rolled pickled plates remove the surface oxide scale, the surface quality of the steel is improved, and it is convenient for welding, oiling and painting. 2. The dimensional accuracy is high. After leveling, the plate shape can be changed to a certain extent, thereby reducing the deviation of unevenness. 3. Improve the surface finish and enhance the appearance effect. 4. It can reduce environmental pollution caused by users’ scattered pickling. Compared with cold-rolled sheets, the advantage of pickled sheets is that they can effectively reduce purchase costs while ensuring the surface quality requirements. Many companies have put forward higher and higher requirements for the high performance and low cost of steel. With the continuous advancement of steel rolling technology, the performance of hot-rolled sheet is approaching that of cold-rolled sheet, so that “replacement of cold with heat” is technically realized. It can be said that the pickled plate is a product with a relatively high performance-to-price ratio between the cold-rolled plate and the hot-rolled plate, and has a good market development prospect. However, the use of pickled plates in various industries in my country has just started. The production of professional pickled plates began in September 2001 when Baosteel’s pickling production line was put into operation.

The classification and symbols of tinned steel sheet and steel strip are as follows

| Class method | Category | Symbol |

| According to the amount of tin plating | Equal thickness tin plating E1, E2, E3, E4 | |

| According to the hardness level | T50、T52、T57、T61、T65、T70 | |

| By surface condition | Smooth | G |

| Stone grain surface | S | |

| Hemp noodles | M | |

| By passivation method | Low chromium passivation | L |

| Chemical passivation | H | |

| Cathode electrochemical passivation | Y | |

| According to the amount of oil | Lightly oiled | Q |

| Repaint | Z | |

| By surface quality | One group | Ⅰ |

| Two groups | Ⅱ |

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Manufacturing Companies for Brass Rod - Galvanized Steel Coil – JINBAICHENG , The product will supply to all over the world, such as: Muscat, Montreal, Lisbon, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.