Leading Manufacturer for Gi Plate - Galvanized Thin Steel Coil – JINBAICHENG

Leading Manufacturer for Gi Plate - Galvanized Thin Steel Coil – JINBAICHENG Detail:

Definition of plating

(1) Normal spangle coating

In the normal solidification process of the zinc layer, zinc grains grow freely to form a coating with obvious spangle morphology.

(2) minimized spangle coating

During the solidification of the zinc layer, the zinc crystal grains are artificially restricted to form the smallest possible spangle coating.

(3) Spangle-free coating

It is obtained by adjusting the chemical composition of the plating solution, which does not have a visible spangle morphology and has a uniform surface coating.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing bath is heat treated to form an alloy layer of zinc and iron throughout the coating. This coating has a dark gray appearance without metallic luster, and is easy to powder during the violent forming process. In addition to cleaning, the coating can be painted directly without further treatment.

(5) differential coating

For both sides of the galvanized steel sheet, coatings with different zinc layer weights are required.

(6) Smooth skin pass

Smoothing is a kind of cold rolling of galvanized steel sheet with a small amount of deformation for one or several of the following purposes. Improve the appearance of the galvanized steel sheet or be suitable for decorative coating; temporarily minimize the slip line (Lüdes line) or crease generated when the finished product is processed

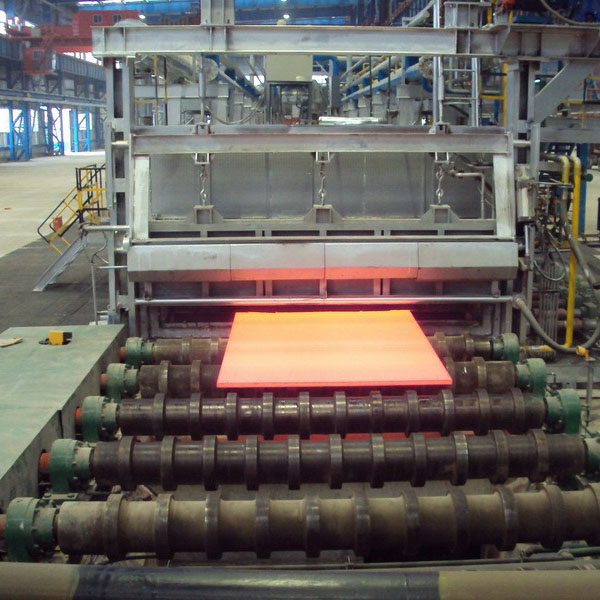

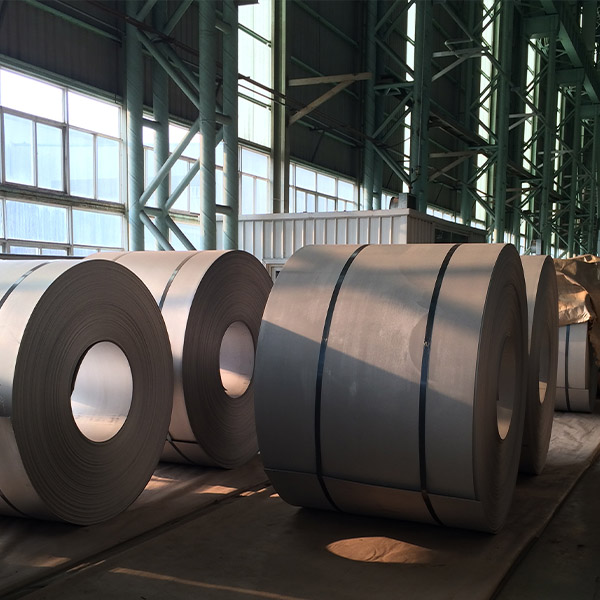

Product Display

Product advantages

Passivation treatment of the galvanized layer can reduce folding rust (white rust) under moisture storage and transportation conditions. However, the anti-corrosion performance of this chemical treatment is limited, and it hinders the adhesion of most coatings. This kind of treatment is generally not used on the zinc-iron alloy coating. In addition to the smooth surface, as a rule, the manufacturer will passivate other types of zinc coatings.

Oiling can reduce the corrosion of steel plates under humid storage and transportation conditions. After passivation treatment of steel plates and steel strips, repainting oil will further reduce the corrosion under humid storage conditions. The oil layer should be able to be removed with a degreaser that does not damage the zinc layer.

Product detail pictures:

Related Product Guide:

All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for Leading Manufacturer for Gi Plate - Galvanized Thin Steel Coil – JINBAICHENG , The product will supply to all over the world, such as: Mauritius, Leicester, Hanover, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!