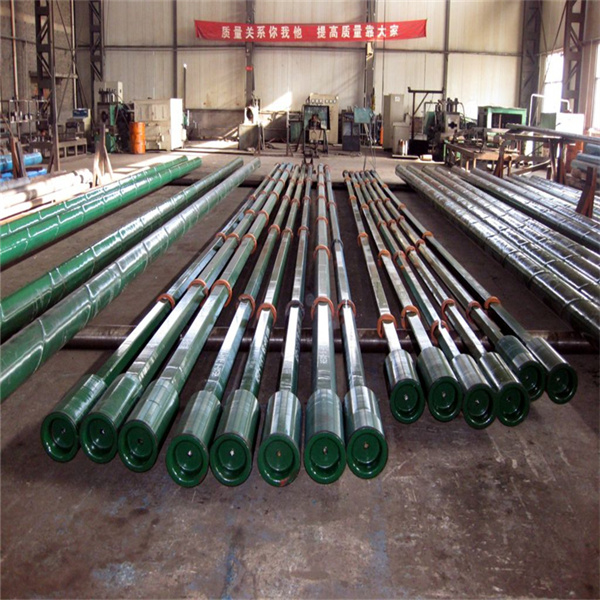

Integral Spiral Heavy Weight Drill Pipe

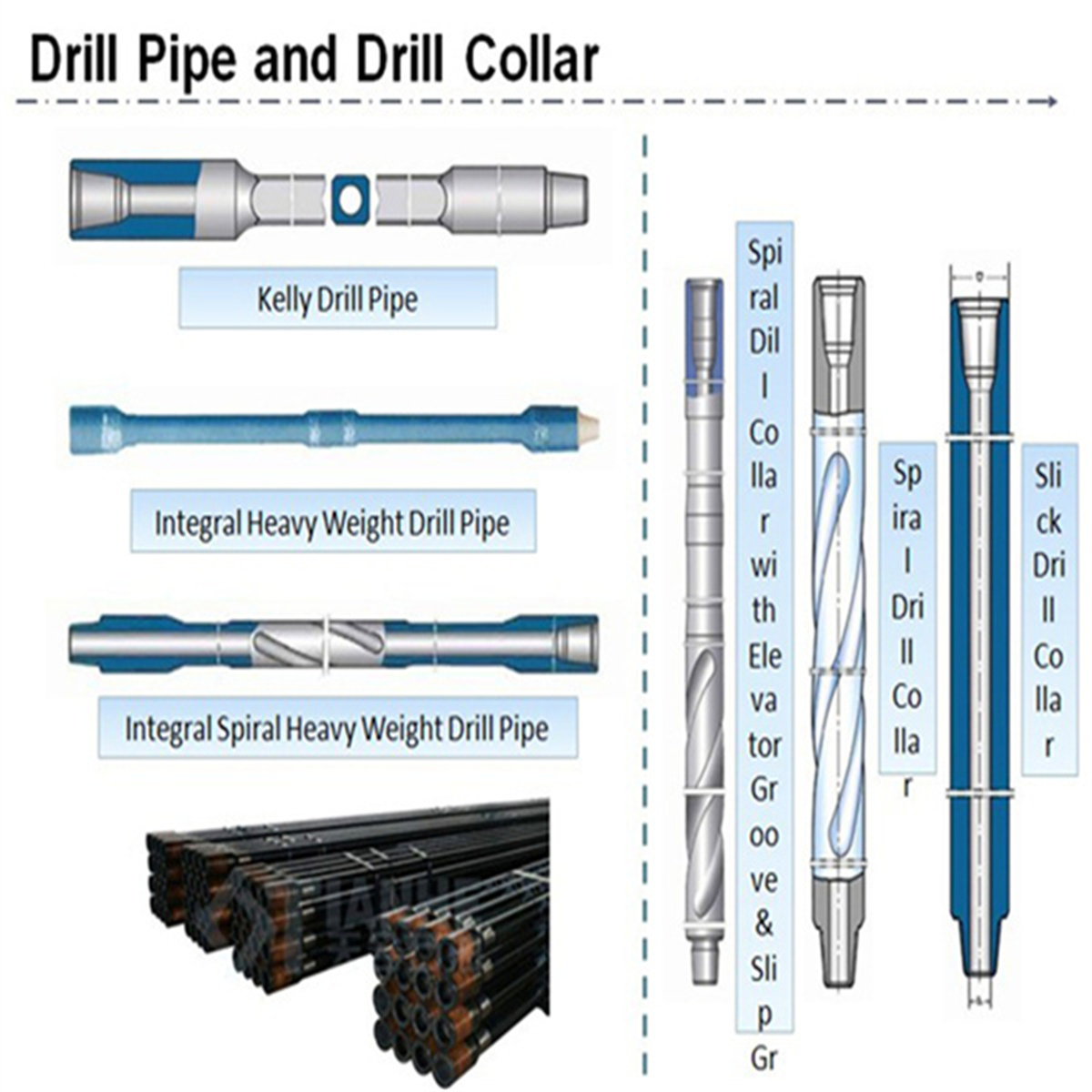

Drill pipe is one of the necessary components to any drilling rig designed to extract oil or other liquid materials from the ground. The drill pipe is not used for extraction. Instead, the hollow tubes pump drilling fluids downward to the bit and back out again as needed to reduce friction and heat buildup. Drill pipe transferred drilling torque to drill bit for drilling under the oil well. It bears complicated strength subject to pulling, loading, pressing, torsion and bending. Standard heavy weight drill pipe tube is manufactured from AISI 1340 steel or equivalent while the tool joints are supplied with AISI 4137H / 4145H modified alloy steel material.

| Size (in) |

Product Code |

O.D.

(in) |

I.D.

(in) |

Tool Joint O.D.(in) |

Tool Joint I.D.(in) |

Connection | Max.elevator diameter (in) |

Central upset dia. (in) |

Mid.drift dia. size (in) |

|

3 1/2 |

SCO07-03000 | 3 1/2 | 2 1/4 | 4 3/4

(4 7/8,5) |

2 1/4 | NC38 | 3 7/8 | 4 | 2 |

| SCO07-03001 | 2 1/16 | 2 1/16 | 1 13/16 | ||||||

| 4 | SCO07-04000 | 4 | 2 1/2 | 5 1/4 | 2 1/2 | NC40 | 4 3/16 | 4 1/2 | 2 1/4 |

| SCO07-04001 | 2 9/16 | 2 9/16 | 2 5/16 | ||||||

| 5 | SCO07-05000 | 4 1/2 | 2 11/16 | 6 1/4 | 2 11/16 | NC46 | 4 11/16 | 5 | 2 7/16 |

| SCO07-05001 | 2 3/4 | 2 3/4 | 2 1/2 | ||||||

| SCO07-05002 | 2 13/16 | 2 13/16 | 2 9/16 | ||||||

| 6 | SCO07-06000 | 5 | 3 | 6 5/8 | 3 | NC50 | 5 1/8 | 5 1/2 | 2 3/4 |

| 5 1/2 | SCO07-07000 | 5 1/2 | 3 1/4 | 7

(7 1/4, 7 1/2) |

3 1/4 | 5 1/2 FH | 5 11/16 | 6 | 3 |

| SCO07-07001 | 3 3/8 | 3 3/8 | 3 1/8 | ||||||

| SCO07-07002 | 3 7/8 | 3 7/8 | 3 5/8 | ||||||

| SCO07-07003 | 4 | 4 | 3 3/4 | ||||||

| 6 5/8 | SCO07-08000 | 6 5/8 | 4 | 8

(8 1/4,8 1/2) |

4 | 6 5/8 FH | 6 15/16 | 7 1/8 | 3 3/4 |

| SCO07-08001 | 4 1/2 | 4 1/2 | 4 1/4 | ||||||

| SCO07-08002 | 5 | 4 3/4 |

We standard heavy weight drill pipe assembly is made up of pin and box tool joints and a heavy weight tube with center upset or wear pad. This configuration helps to prevent stress concentration which could otherwise occur and allows directional drilling with controlled torque and reduce differential pressure sticking.

We also offers DPM-HW95 and DPM-HW105 high strength welded HWDP with 95,000 PSI and 105,000 PSI SMYS tubes and 120 KSI tool joints.

Reduces drilling cost (check also drilling cost per foot) by eliminating Drill Pipe failures in the transition zone.

Significantly increases performance of small rigs through the ease of handling.

Provides substantial savings in directional drilling by replacing most of the Drill Collars string, reducing down hole drilling Torque and Drag.

Reduces tendency to become Deferentially stuck. This is due to the fact that large diameters are easier to stick than small diameters.

You are in the right place to know many tips to choose the suitable water well drill pipe to have less downtime and to save costs by buying the best and long-lasting ones from the many available. A few tips include

1-Check for specific features that make the drill efficient, reliable, and durable to make the most ROI or return on investment.

2-Look for two engine mud rotary drills, one for rotary or hydraulic systems and the other to control and ensure the unit operates with optimum speed and efficiency.

3-Choose the right rotary drill bit to increase the performance and longevity of the drilling pipes.