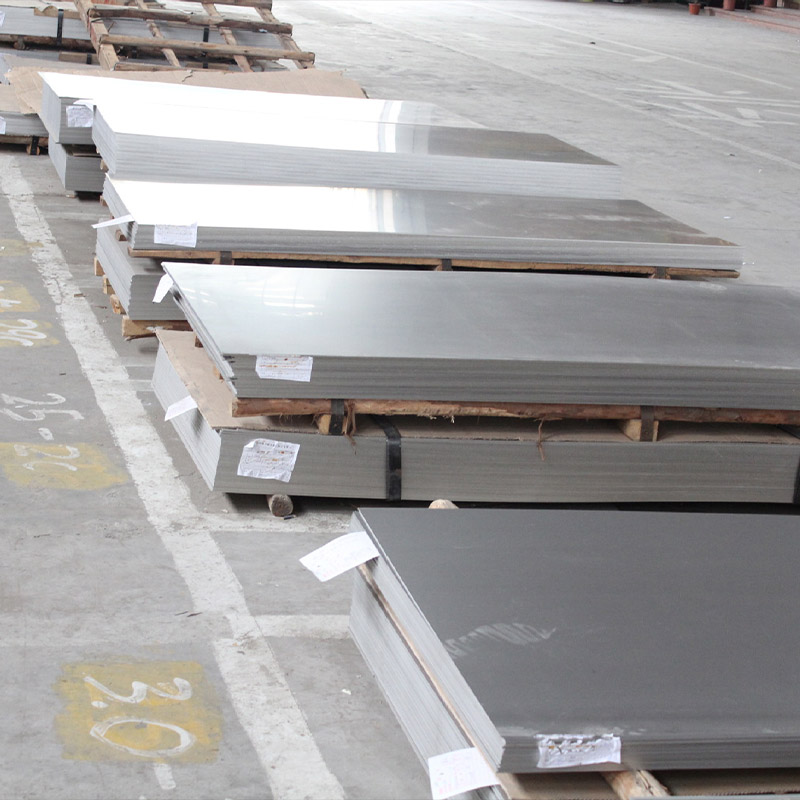

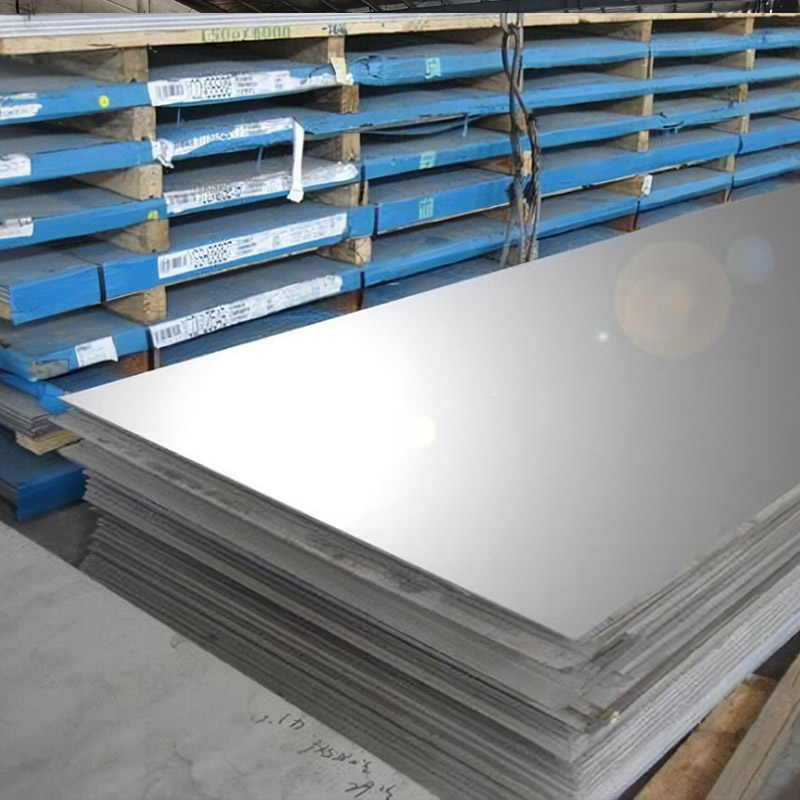

Hot Rolled Stainless Steel Plate

It is required to be able to withstand the corrosion of oxalic acid, sulfuric acid iron sulfate, nitric acid, nitric acid hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid, acetic acid and other acids. It is widely used in chemical industry, food, medicine, papermaking, petroleum, atomic energy and other industries, as well as various parts of buildings, kitchenware, tableware, vehicles and household appliances. In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of various stainless steel plates meet the requirements, the steel plates must undergo heat treatment such as annealing, solution treatment and aging treatment before delivery.

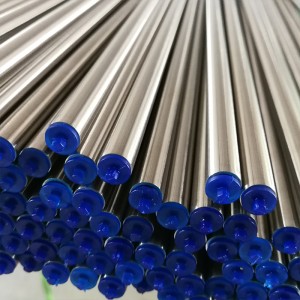

Stainless steel plate has smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion of acid, alkaline gas, solution and other media. It is a kind of alloy steel that is not easy to rust, but it is not absolutely rust free.

The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and internal structure. Chromium plays a major role. Chromium has high chemical stability, can form a passive film on the steel surface, isolate the metal from the outside, protect the steel plate from oxidation and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

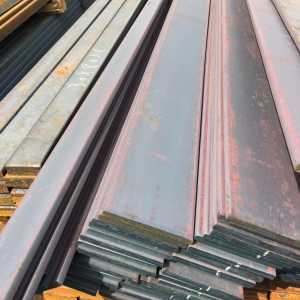

According to the manufacturing method, there are two kinds of hot rolling and cold rolling, including thin plate with thickness of 0.5-4 mm and thick plate with thickness of 4.5-35 mm.

According to the structural characteristics of steel grade, it can be divided into 5 types: austenite type, austenite ferrite type, ferrite type, martensite type and precipitation hardening type.

High strength stainless steel plate with excellent corrosion resistance, bending processability and toughness of welding parts, as well as stamping processability of welding parts and its manufacturing method. Specifically, the stainless steel plate containing Si, Mn, P, s, Al and Ni with an appropriate content of less than 0.02% of C, less than 0.02% of N, more than 11% of Cr and less than 17%, and meeting the requirements of 12 ≤ Cr Mo 1.5si ≤ 17, 1 ≤ Ni 30 (c n) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3mo ≥ 16.0, 0.006 ≤ C n ≤ 0.030 shall be heated to 850 ~ 1250 ℃, and then the heat treatment shall be carried out at a cooling rate of more than 1 ℃ / s. In this way, it can become a high-strength stainless steel plate with martensite content of more than 12% by volume, high strength of more than 730mpa, corrosion resistance and bending processability, and excellent toughness of welding heat affected zone. The stamping performance of welded parts can be significantly improved by reusing Mo, B, etc.