Good Quality Steel Pipe - Hot Dip Galvanized Steel – JINBAICHENG

Good Quality Steel Pipe - Hot Dip Galvanized Steel – JINBAICHENG Detail:

Weight factor

Nominal wall thickness (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Coefficient parameters (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Note: The mechanical properties of steel is an important index to ensure the final use performance (mechanical properties) of the steel, and it depends on the chemical composition of the steel and the heat treatment system. In the steel pipe standard, according to different application requirements, the tensile properties (tensile strength, yield strength or yield point, elongation), hardness and toughness indexes are specified, as well as high and low temperature properties required by users.

Steel grades: Q215A; Q215B; Q235A; Q235B.

Test pressure value/Mpa: D10.2-168.3mm is 3Mpa; D177.8-323.9mm is 5Mpa

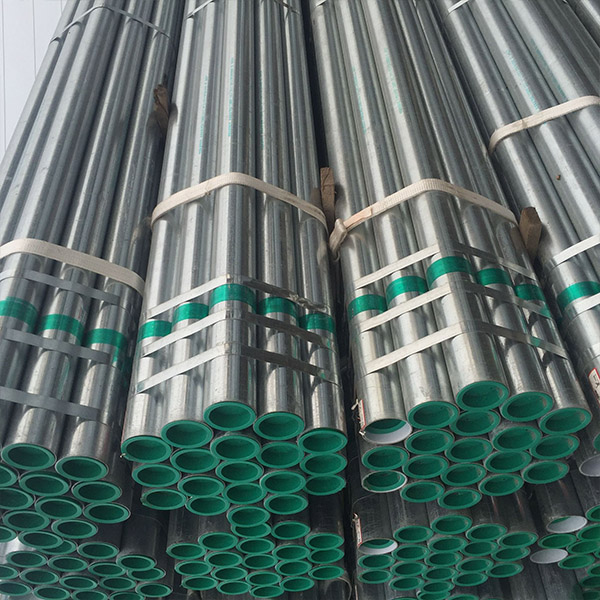

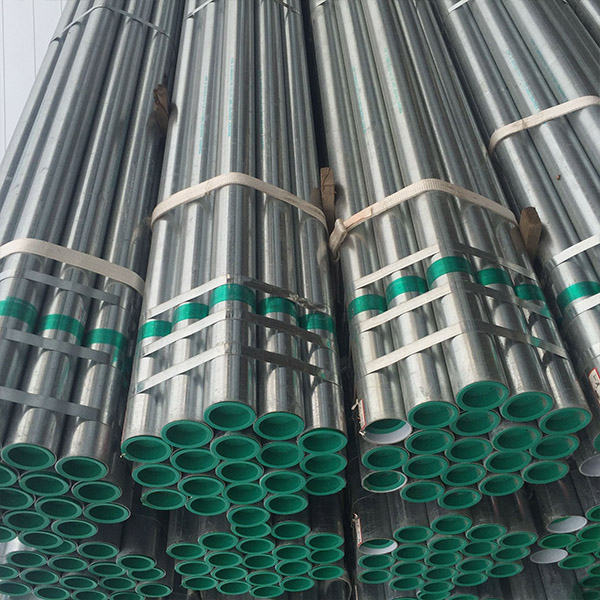

Product Display

Current national standard

National standards and size standards for galvanized pipes

GB/T3091-2015 Welded steel pipe for low pressure fluid transportation

GB/T13793-2016 Longitudinal electric welded steel pipe

GB/T21835-2008 welded steel pipe size and unit length weight

Production steps

The process flow is: black tube-alkaline washing-water washing-pickling-water rinsing-soaking aid-drying-hot dip galvanizing-external blowing-internal blowing-air cooling-water cooling -Passivation-water rinsing-inspection-weighing-storage.

Instructions for use

The commonly said galvanized pipes, galvanized pipes are used for gas, and the kind of iron pipes used for heating are also galvanized pipes. Galvanized pipes are used as water pipes. After several years of use, a lot of rust and dirt are generated in the pipes, and the yellow water that flows out not only pollutes the sanitary ware , And it is mixed with bacteria that breed on the uneven inner wall, and the corrosion causes the high content of heavy metals in the water, which seriously endangers the health of the human body.

Connection method

Galvanized steel pipe connection method: threaded, welded.

Roll groove connection

(1) Cracking of roll groove weld

1. Smooth the inner wall welding ribs of the pressure groove part of the nozzle to reduce the resistance of the rolling groove.

2, Adjust the axis of the steel pipe and the rolling grooving equipment, and require the steel pipe and the rolling grooving equipment to be level.

3. Adjust the groove pressing speed, and the groove forming time can not exceed the stipulation, apply force evenly and slowly.

(2) Roll groove steel pipe fracture

1. Smooth the inner wall welding ribs of the pressure groove part of the pipe mouth to reduce the resistance of the rolling groove.

2, Adjust the axis of the steel pipe and the rolling grooving equipment, requiring the steel pipe and the rolling grooving equipment to be level.

3. Adjust the pressing speed, the pressing speed cannot exceed the stipulation, apply force evenly and slowly.

4. Check the width and model of the support roller and pressure roller of the rolling groove equipment, and check whether there is a mismatch in the size of the two rollers, which may cause seizure.

5. Use a vernier caliper to check whether the groove of the steel pipe is specified.

(3) The groove formed by the rolling groove machine should meet the following requirements

1, The surface of the pipe end to the groove section should be smooth and free of unevenness and roll marks.

2, The center of the groove should be concentric with the pipe wall, the width and depth of the groove should meet the requirements, and check whether the clamp part type is correct.

3. Apply lubricant on the rubber sealing ring and check whether the rubber sealing ring is damaged. The lubricant must not be oil lubricant.

Welded connection

1. The pipe mouth of the galvanized steel pipe is not in a straight line and there is a problem with the oblique mouth of the steel pipe after butting. It is recommended to cut off the pipe head for a short period of time before processing.

2, After the galvanized steel pipe nozzles are connected, the two nozzles are not tightly connected, resulting in uneven thickness of the welded joint; and the pipe is elliptical due to its own reasons or transportation bumps. It is recommended to cut off the pipe head for a short period of time. Process again.

3. After the nozzles of galvanized steel pipes are butted, blisters appear at the nozzles:

4. Due to technical reasons during welding.

5. There are zinc nodules in the nozzle, which can cause welding difficulties and blisters. If the zinc nodules are too large and too many pipes, simple zinc nodules should be removed.

Wire connection

1, Threaded buckle: The pipe hoop and the threaded buckle can not be completely contacted, loosen, cut off the random buckle part, and re-install the thread.

2. The steel pipe thread and the pipe hoop thread do not match and cannot be connected. The pipe hoop should be replaced or the equipment should be adjusted and re-threaded.

3. Missing print after the steel pipe is threaded: Measure whether the wall thickness of the steel pipe can meet the standard thickness requirements of the threaded pipe

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Good Quality Steel Pipe - Hot Dip Galvanized Steel – JINBAICHENG , The product will supply to all over the world, such as: Bahrain, Ecuador, Czech Republic, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!