Factory wholesale Lead Bar - Cold-Pressed Pattern Steel Coil – JINBAICHENG

Factory wholesale Lead Bar - Cold-Pressed Pattern Steel Coil – JINBAICHENG Detail:

Product Introduction

Origin: Shandong, China

Brand name: jinbaicheng

Application: cutting board and making corrugated board

Type: steel coil

Thickness: 0.12-4.0

Width: 1001-1250mm

Certificate: BIS, ISO9001, ISO, SGS, sai

Grade: SGCC / CGCC / dx51d

Coating: z181-z275

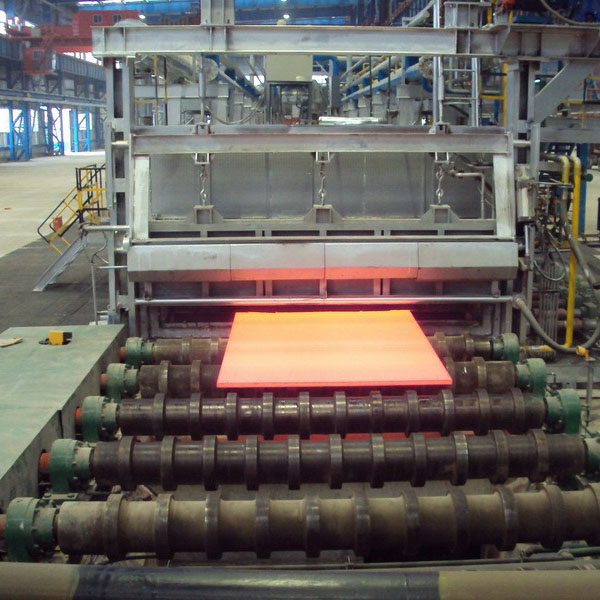

Technology: Based on hot rolling

Tolerance: ± 10%

Sequin type: ordinary Sequin

Oil or no oil: lightly oil

Hardness: full hard

Delivery time: 15-21 days

Zinc coating: 30-600g / m2

Coil weight: 3-5t or as required

Coil ID : 508mm/610mm

Payment terms: T / T, L / C, Kunlun bank,

Minimum order quantity: 25 MT (one 20 foot full container)

Delivery time: within 15-20 days

Standard: astma36, jisg3302

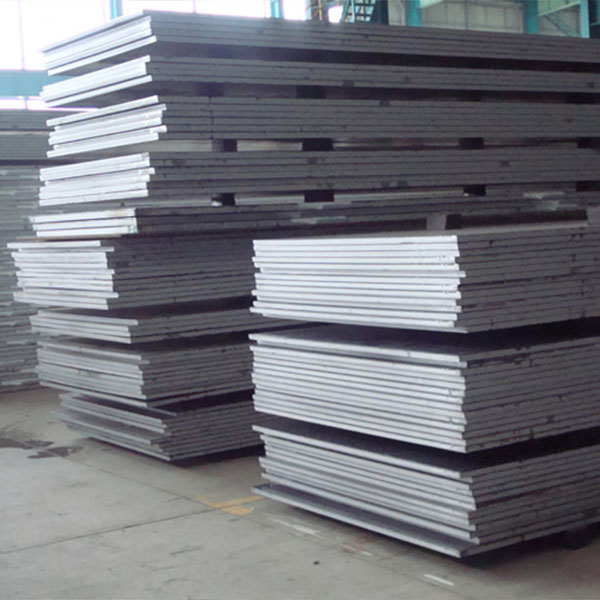

The formed coils are mainly hot-rolled coils and cold-rolled coils. Hot rolled coil is a processed product before the billet is recrystallized. Cold rolled coil is the subsequent processing of hot rolled coil. The general weight of steel coil is about 15-30T. my country’s hot-rolling production capacity continues to expand, there are already dozens of hot-rolling production lines, and some projects are about to start construction or put into operation.

General users have no unwinding equipment or limited usage. Therefore, the subsequent processing of steel coils will be a very promising industry. Of course, the larger steel mills currently have their own uncoiling and flattening projects.

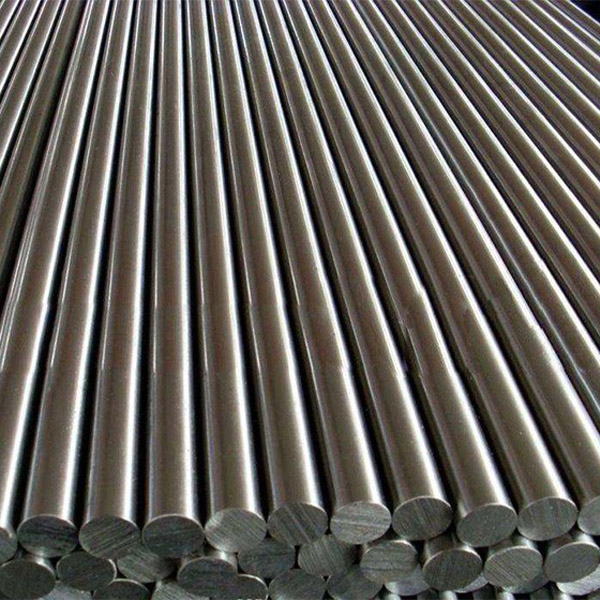

Product Display

Surface quality is divided into two levels

Ordinary precision: the surface of the steel plate is allowed to have a thin layer of iron oxide scale, rust, surface roughness caused by the peeling of iron oxide scale, and other local defects whose height or depth exceeds the allowable deviation. Unobvious burrs and individual traces whose height does not exceed the pattern height are allowed on the pattern. The maximum area of a single defect does not exceed the square of the grain length.

Higher precision: Thin oxide scale, rust, and other local defects whose height or depth does not exceed half of the thickness tolerance are allowed on the surface of the steel plate. The pattern is intact, and local slight burrs whose height does not exceed half of the thickness tolerance are allowed on the pattern.

Scope of application

Automobile industry

Hot-rolled pickled oil-coated sheet is a new type of steel required by the automotive industry. Its better surface quality, thickness tolerance, and processing performance can replace body panels and auto parts produced by cold-rolled sheets in the past, thereby reducing raw materials The cost is about 10%. With the development of the economy, the production of automobiles has also increased significantly, and the use of plates has continued to increase. The original design of many vehicle models in the domestic automobile industry requires the use of hot-rolled pickled plates, such as: car subframes, wheel spokes, front and rear Due to the insufficient supply of domestic hot-rolled pickling plates for bridge assemblies, truck box plates, protective nets, automobile beams and spare parts, automobile factories generally use cold plates or hot plates instead or pick them by themselves.

Machinery Industry

Hot-rolled pickled plates are mainly used in textile machinery, mining machinery, fans and some general machinery. Such as the manufacture of compressor housings and upper and lower covers for household refrigerators and air conditioners, pressure vessels and mufflers for power compressors, and bases for screw air compressors. Among them, household refrigerators and air-conditioning compressors use the most pickling plates, and the deep drawing performance of the pickling plates is relatively high. The materials are mainly SPHC, SPHD, SPHE, SAPH370, the thickness range is 1.0-4.5mm, and the required specifications are 2.0-3.5mm. According to relevant data, in the first half of this year, refrigerator compressors and air-conditioning compressors required hot-rolled pickling plates of 80,000 tons and 135,000 tons, respectively. The fan industry now mainly uses cold-rolled plates and hot-rolled plates. Hot-rolled pickled plates can be used instead of cold plates to manufacture impellers, shells, flanges, mufflers, bases, platforms, etc., of blowers and ventilators.

Other industry

Other industry applications mainly include bicycle parts, various welded pipes, electrical cabinets, highway guardrails, supermarket shelves, warehouse shelves, fences, water heater tanks, barrels, iron ladders, and various shapes of stamping parts. With the continuous development of the economy, zero-part processing is spreading across all industries, and processing plants have sprung up rapidly. The demand for plates has greatly increased, and the potential demand for hot-rolled pickled plates has also increased.

Main advantage

Pickling plate is made of high-quality hot-rolled sheet as raw material. After the pickling unit removes the oxide layer, trims and finishes, the surface quality and use requirements (mainly cold-formed or stamping performance) are between hot-rolled and cold-rolled The intermediate product between the plates is an ideal substitute for some hot-rolled plates and cold-rolled plates. Compared with hot-rolled plates, the main advantages of pickled plates are: 1. Good surface quality. Because the hot-rolled pickled plates remove the surface oxide scale, the surface quality of the steel is improved, and it is convenient for welding, oiling and painting. 2. The dimensional accuracy is high. After leveling, the plate shape can be changed to a certain extent, thereby reducing the deviation of unevenness. 3. Improve the surface finish and enhance the appearance effect. 4. It can reduce environmental pollution caused by users’ scattered pickling. Compared with cold-rolled sheets, the advantage of pickled sheets is that they can effectively reduce purchase costs while ensuring the surface quality requirements. Many companies have put forward higher and higher requirements for the high performance and low cost of steel. With the continuous advancement of steel rolling technology, the performance of hot-rolled sheet is approaching that of cold-rolled sheet, so that “replacement of cold with heat” is technically realized. It can be said that the pickled plate is a product with a relatively high performance-to-price ratio between the cold-rolled plate and the hot-rolled plate, and has a good market development prospect. However, the use of pickled plates in various industries in my country has just started. The production of professional pickled plates began in September 2001 when Baosteel’s pickling production line was put into operation.

The classification and code of steel plates and strips are as follows

| Class method | Category | Code |

| According to purpose | Building exterior | JW |

| Building internal use | JN | |

| Household appliances | JD | |

| According to surface condition | Coated board | TC |

| Printed board | YH | |

| Printed board | YaH | |

| According to the type of paint | Polyester for external use | WZ |

| Internal polyester | NZ | |

| Silicon modified polyester | GZ | |

| Acrylic for external use | WB | |

| Acrylic for internal use | NB | |

| Plastisol | SJ | |

| Organosol | YJ | |

| According to the type of substrate | Low carbon steel cold rolled steel strip | DL |

| Small spangle flat steel belt | XP | |

| Large spangle flat steel belt | DP | |

| Zinc-iron alloy steel strip | XT | |

| Electro-galvanized steel strip | DX |

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Factory wholesale Lead Bar - Cold-Pressed Pattern Steel Coil – JINBAICHENG , The product will supply to all over the world, such as: Cancun, Greek, Romania, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!