Factory Price Cold Rolled Steel Sheet In Coil - Bimetal Composite Wear-Resistant Steel Plate – JINBAICHENG

Factory Price Cold Rolled Steel Sheet In Coil - Bimetal Composite Wear-Resistant Steel Plate – JINBAICHENG Detail:

Product Introduction

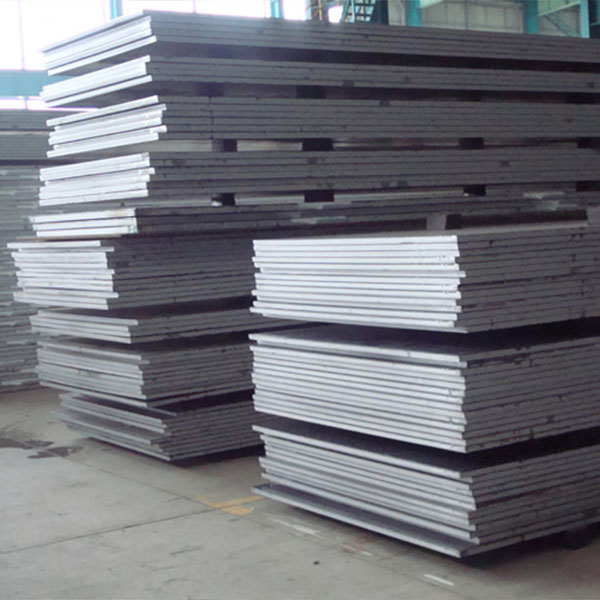

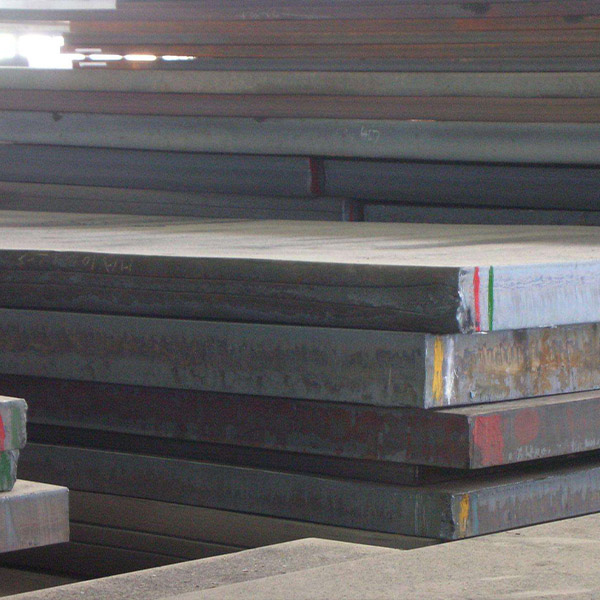

There is a metallurgical bond between the wear-resistant layer of the wear-resistant steel plate alloy and the substrate. Through special equipment and automatic welding process, the high-hardness self-shielding alloy welding wire is uniformly welded on the base material. The number of composite layers is one to two or even multiple layers. During the composite process, due to the different shrinkage ratio of the alloy, uniform transverse cracks appear, which is a significant feature of the wear-resistant steel plate.

The wear-resistant steel plate has high wear resistance and good impact performance. It can be cut, bent, welded, etc., and can be connected to other structures by welding, plug welding, bolt connection, etc., which saves time in the maintenance on-site process It is widely used in metallurgy, coal, cement, electric power, glass, mining, building materials, bricks and tiles and other industries. Compared with other materials, it has a high cost performance and has been favored by more and more industries and manufacturers. .

Product Display

Classification

According to the hardness and welding process, the main brands of wear-resistant plates are: NM360, NM400, NM450, NM500.

application

1) Thermal power plant: medium-speed coal mill cylinder liner, fan impeller socket, dust collector inlet flue, ash duct, bucket turbine liner, separator connecting pipe, coal crusher liner, coal scuttle and crusher Machine liner, burner burner, coal falling hopper and funnel liner, air preheater bracket protection tile, separator guide vane. The above parts do not have high requirements on the hardness and wear resistance of the wear-resistant steel plate, and the wear-resistant steel plate with a thickness of 6-10mm in the material of NM360/400 can be used.

2) Coal yard: feeding trough and hopper lining, hopper bushing, fan blades, pusher bottom plate, cyclone dust collector, coke guide liner, ball mill lining, drill stabilizer, screw feeder bell and base Seat, kneader bucket lining, ring feeder, dump truck bottom plate. The working environment of the coal yard is harsh, and there are certain requirements for the corrosion resistance and wear resistance of the wear-resistant steel plate. It is recommended to use the wear-resistant steel plate of NM400/450 HARDOX400 with a thickness of 8-26mm.

3) Cement plant: chute lining, end bushing, cyclone dust collector, powder separator blades and guide blades, fan blades and lining, recycling bucket lining, screw conveyor bottom plate, piping components, frit cooling plate Lining, conveying trough lining board. These parts also require wear-resistant steel plates with better wear resistance and corrosion resistance, and wear-resistant steel plates with a thickness of 8-30mmd made of NM360/400 HARDOX400 can be used.

4) Loading machinery: unloading mill chain plate, hopper liner, grab blade plate, automatic dump truck dump board, dump truck body. This requires wear-resistant steel plates with extremely high wear-resistant strength and hardness. It is recommended to use wear-resistant steel plates with a material of NM500 HARDOX450/500 and a thickness of 25-45MM.

5) Mining machinery: linings, blades, conveyor linings and baffles of mineral materials and stone crushers. Such parts require extremely high wear resistance, and the available material is NM450/500 HARDOX450/500 wear-resistant steel plates with a thickness of 10-30mm.

6) Construction machinery: cement pusher tooth plate, concrete mixing tower, mixer lining plate, dust collector lining plate, brick machine mold plate. It is recommended to use wear-resistant steel plates made of NM360/400 with a thickness of 10-30mm.

7) Construction machinery: loaders, bulldozers, excavator bucket plates, side blade plates, bucket bottom plates, blades, rotary drilling rig drill rods. This type of machinery requires particularly strong and wear-resistant steel plates with extremely high wear-resistant strength. The available materials are NM500 HARDOX500/550/600 high-strength wear-resistant steel plates with a thickness of 20-60mm.

8) Metallurgical machinery: iron ore sintering machine, conveying elbow, iron ore sintering machine liner, scraper liner. Because this kind of machinery requires high temperature resistant and extremely hard wear-resistant steel plates. Therefore, it is recommended to use HARDOX600HARDOXHiTuf series wear-resistant steel plates.

9) Wear-resistant steel plates can also be used in sand mill cylinders, blades, various freight yard, terminal machinery and other parts, bearing structural parts, railway wheel structural parts, rolls, etc.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for Factory Price Cold Rolled Steel Sheet In Coil - Bimetal Composite Wear-Resistant Steel Plate – JINBAICHENG , The product will supply to all over the world, such as: Angola, Indonesia, Mauritius, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

We have been looking for a professional and responsible supplier, and now we find it.