Factory For Faflangenge – NM500 High-Strength Wear-Resistant Steel Plate – JINBAICHENG

Factory For Faflangenge – NM500 High-Strength Wear-Resistant Steel Plate – JINBAICHENG Detail:

Product naming

N is the first pinyin letter of “Nai” in “Wear”.

M is the first pinyin letter of “mill” in “wear-resistant”.

500 is the Brinell hardness value HB value. (500 hardness value is broad, domestic NM500 hardness value is about 500.)

Grade classification: NM500ANM500B

Heat treatment: quenching and tempering (quenching + tempering).

Application: NM500 wear-resistant steel plate is widely used in engineering machinery, mining machinery, coal mining machinery, environmental protection machinery, metallurgical machinery, abrasive tools, bearings and other product parts.

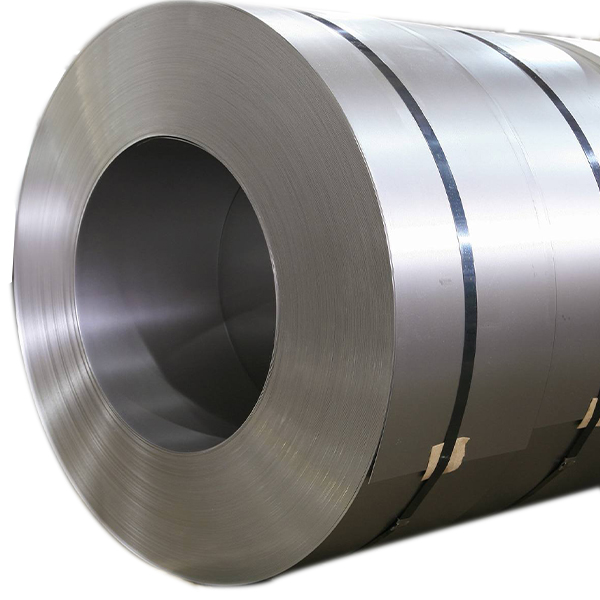

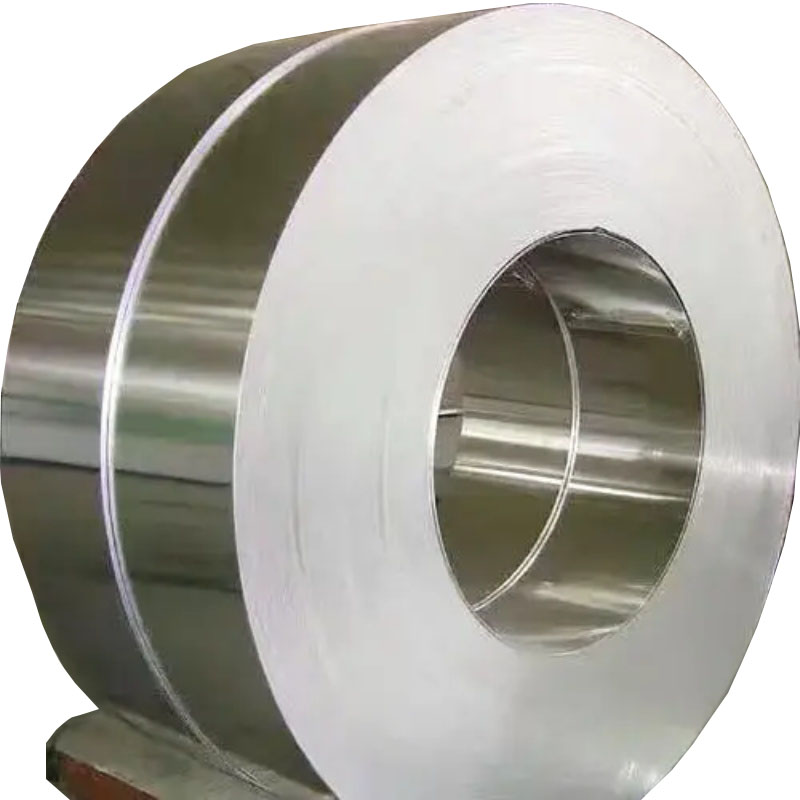

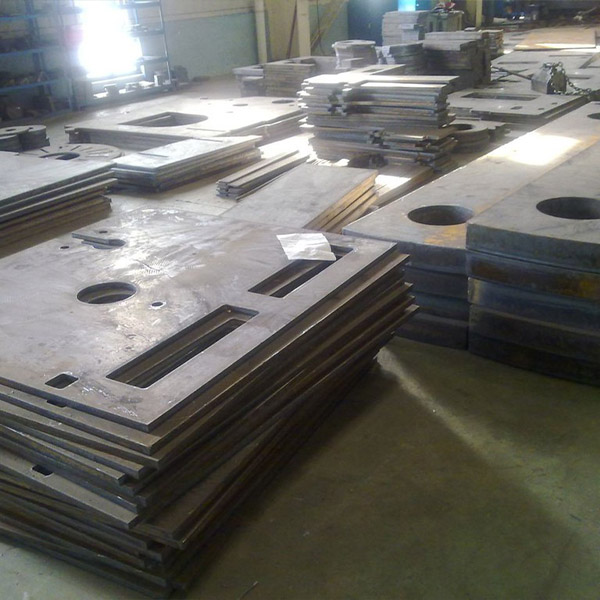

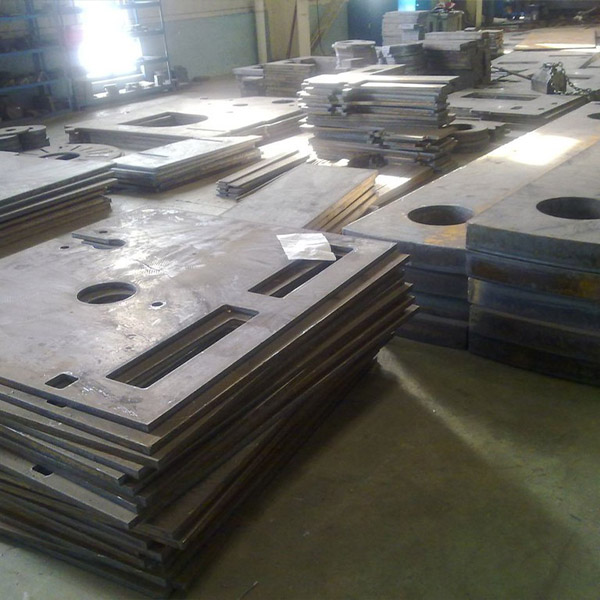

Product Display

Product Usage

Construction machinery, mining machinery, coal mining machinery, environmental protection machinery, metallurgical machinery and other manufacturing enterprises. Used for excavators, loaders, bulldozer bucket plates, blade plates, side blade plates, blades, crusher liners.

Wear plate use:

1) Thermal power plant: medium-speed coal mill cylinder liner, fan impeller socket, dust collector inlet flue, ash duct, bucket turbine liner, separator connecting pipe, coal crusher liner, coal scuttle and crusher Machine liner, burner burner, coal falling hopper and funnel liner, air preheater bracket protection tile, separator guide vane. The above parts do not have high requirements on the hardness and wear resistance of the wear-resistant steel plate, and the wear-resistant steel plate with a thickness of 6-10mm in the material of NM360/400 can be used.

2) Coal yard: feeding trough and hopper lining, hopper bushing, fan blades, pusher bottom plate, cyclone dust collector, coke guide liner, ball mill lining, drill stabilizer, screw feeder bell and base Seat, kneader bucket lining, ring feeder, dump truck bottom plate. The working environment of the coal yard is harsh, and there are certain requirements for the corrosion resistance and wear resistance of the wear-resistant steel plate. It is recommended to use the wear-resistant steel plate of NM400/450 HARDOX400 with a thickness of 8-26mm.

3) Cement plant: chute lining, end bushing, cyclone dust collector, powder separator blades and guide blades, fan blades and lining, recycling bucket lining, screw conveyor bottom plate, piping components, frit cooling plate Lining, conveying trough lining board. These parts also require wear-resistant steel plates with better wear resistance and corrosion resistance, and wear-resistant steel plates with a thickness of 8-30mmd made of NM360/400 HARDOX400 can be used.

4) Loading machinery: unloading mill chain plate, hopper liner, grab blade plate, automatic dump truck dump board, dump truck body. This requires wear-resistant steel plates with extremely high wear-resistant strength and hardness. It is recommended to use wear-resistant steel plates with a material of NM500 HARDOX450/500 and a thickness of 25-45MM.

5) Mining machinery: linings, blades, conveyor linings and baffles of mineral materials and stone crushers. Such parts require extremely high wear resistance, and the available material is NM450/500 HARDOX450/500 wear-resistant steel plates with a thickness of 10-30mm.

6) Construction machinery: cement pusher tooth plate, concrete mixing tower, mixer lining plate, dust collector lining plate, brick machine mold plate. It is recommended to use wear-resistant steel plates made of NM360/400 with a thickness of 10-30mm.

7) Construction machinery: loaders, bulldozers, excavator bucket plates, side blade plates, bucket bottom plates, blades, rotary drilling rig drill rods. This type of machinery requires particularly strong and wear-resistant steel plates with extremely high wear-resistant strength. The available materials are NM500 HARDOX500/550/600 high-strength wear-resistant steel plates with a thickness of 20-60mm.

8) Metallurgical machinery: iron ore sintering machine, conveying elbow, iron ore sintering machine liner, scraper liner. Because this kind of machinery requires high temperature resistant and extremely hard wear-resistant steel plates. Therefore, it is recommended to use HARDOX600HARDOXHiTuf series wear-resistant steel plates.

9) Wear-resistant steel plates can also be used in sand mill cylinders, blades, various freight yard, terminal machinery and other parts, bearing structural parts, railway wheel structural parts, rolls, etc.

Product detail pictures:

Related Product Guide:

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for Factory For Faflangenge – NM500 High-Strength Wear-Resistant Steel Plate – JINBAICHENG , The product will supply to all over the world, such as: Leicester, Vancouver, Greek, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!