Factory best selling Prices Of Aluminum Sheet Coil - Pressure Vessel Boiler Steel Plate – JINBAICHENG

Factory best selling Prices Of Aluminum Sheet Coil - Pressure Vessel Boiler Steel Plate – JINBAICHENG Detail:

Overview

(1) Definition: In addition to requiring certain strength and toughness, the material is also required to be uniform, and harmful defects are strictly restricted.

(2) Type: According to the composition classification, it can be divided into two categories: carbon steel plate and alloy steel plate; according to the strength classification, it can be divided into high, medium and low pressure steel plates; according to the use environment, it can be divided into high, medium and low temperature steel plates and resistant steel plates. Corrosion of steel plate.

(3) Main production plants and main import producing countries:

①Main domestic production plants: Wugang, Anshan Iron and Steel, Laiwu Steel, Shanghai Iron and Steel, Baotou Steel, Sangang, etc.;

②Major exporting countries and regions abroad: Japan, Russia, Germany, Eastern Europe and other countries and regions.

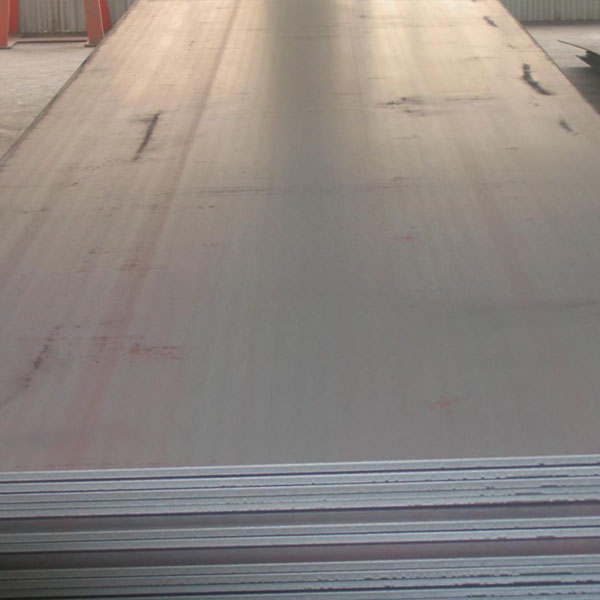

Product Display

Specification

| Boiler plate, container plate calculated weight thickness | ||||

| Nominal thickness | Thickness added value | |||

| ≤1500 | >1500~2500 | >2500~4000 | >4000~4800 | |

| 3.00~5.00 | 0.25 | 0.35 | —- | |

| 6.00~8.00 | 0.3 | 0.45 | —- | |

| 9.00~15.0 | 0.35 | 0.5 | 0.6 | |

| 16.0~25.0 | 0.45 | 0.6 | 0.8 | |

| 26.0~40.0 | 0.5 | 0.7 | 0.9 | |

| 41~60.0 | 0.6 | 0.8 | 1 | |

| 61.0~100 | 0.75 | 1 | 1.2 | |

| 101~150 | 1.1 | 1.3 | 1.5 | |

| 151~200 | 1.3 | 1.5 | 1.6 | |

| 201~250 | 1.5 | 1.7 | 1.9 | |

| 251~300 | 1.7 | 1.9 | 2.1 | |

| 301~400 | 1.9 | 2.1 | 2.3 |

Size specification

The thickness of the pressure vessel plate generally ranges from 5mm to 200mm, and is divided into several thickness specifications during the period. National standards list recommended sheet sizes and allowable deviations. Appearance quality

(1) The shape of the steel plate: such as sickle bend, flatness, right angle, etc.

(2) Surface defects: The surface defects of the steel plate mainly include cracks, scars, flattened bubbles, impurities, bumps, pores, pressed iron oxide scale, etc. Due to safety requirements, pressure vessel steel plates have strict requirements on surface and internal defects. Generally, the above-mentioned defects are not allowed to exist. However, proper methods are allowed to be removed, and the removal site should be flat. Its thickness shall not exceed the allowable difference in the thickness of the steel plate. Generally, no interlayer is allowed. Chemical composition index:

① Carbon steel plate: mainly detects the content of carbon, silicon, manganese, phosphorus, and sulfur. Some carbon steel also contains a certain amount of copper, chromium, nickel, molybdenum, vanadium and other elements. Among them, carbon is the main factor to determine the strength of the steel plate, that is, the strength of the steel plate increases with the increase of the carbon content. The carbon content of carbon steel plates is between 0.16 and 0.33%. Manganese and silicon also have the effect of improving the material and increasing the strength. Silicon: 0.10~0.55%, manganese: 0.4~1.6%. Some standards do not have silicon and manganese requirements for ordinary boiler plates, and copper is less than 0.30%. Other standards such as Japan and Russia do not have copper content requirements. Some high-quality steels contain chromium (less than 0.25%), nickel (less than 0.30%), molybdenum (less than 0.10%), and vanadium (less than 0.03%). The chemical composition of each grade of boiler steel plate is shown in the product standards provided in Table 6-7-3.

Packing

Generally naked or bundled. For the requirements of smoothness and stainless steel plates, boxes or stows or brackets should be used, and they should be wrapped with moisture-proof paper or other materials.

Purpose deep processing technology

Laser tailor-welded blank and continuous variable cross-section board technology

1. Tailor Welded Blanks (Tailor Welded Blanks, TWB) uses laser as the welding heat source to combine and weld several different materials, different thicknesses, and different coatings of steel, stainless steel, aluminum alloy, etc. into a whole plate.

2. Using laser tailored welding technology, it is possible to reasonably combine materials of different thickness sizes and strength levels according to the stress conditions of the structural parts, improve the structural rigidity while reducing the weight of the parts, and also increase the utilization rate of materials and reduce the number of parts. The number of parts in the simplifies the process. Laser tailored welding technology has become the main technical means of automobile lightweight, and it has been applied to the models of many manufacturers. Mainly used in front and rear door inner panels, front and rear longitudinal beams, side panels, floor panels, A, B, and C pillars on the inside of the door, wheel covers and trunk inner panels, etc.

3. Tailor Rolling Blanks (TRB), also called differential thickness plates, refers to the real-time change of the roll gap size through the computer during the rolling process of the steel plate, so that the rolled thin plate has a pre-determined direction along the rolling direction. Custom variable cross-sectional shape.

4. Continuous variable cross-section panel technology has been widely used in the manufacture of body structure parts, such as engine cover, B-pillar, body chassis, motor spacer guide, middle column inner panel, mudguard and crash box, etc., and has been successfully applied to Audi, BMW, Volkswagen, GM and other models.

5. Laser tailored welding and continuous variable cross-section technology change the thickness of the stamping material through different technological means, and are used to solve the problem of different load-bearing capacity requirements for different parts of auto parts under load. Compared with the two, the advantage of tailor-made laser welding technology lies in its flexibility, which can realize the splicing of any position and the splicing of different materials. The advantage of continuous variable cross-section technology is that there is no welding seam, the hardness change along the length direction is relatively gentle, it has better formability, and the surface quality is good, the production efficiency is high, and the cost is low. Luggage, medical equipment, motorcycle shell; automobile, bus inner roof, dashboard; seat backing, door panel, window frame, etc.

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for Factory best selling Prices Of Aluminum Sheet Coil - Pressure Vessel Boiler Steel Plate – JINBAICHENG , The product will supply to all over the world, such as: Slovenia, European, Greece, We're introduced as a one of the growing manufacture supplier and export of our merchandise. Now we have a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.