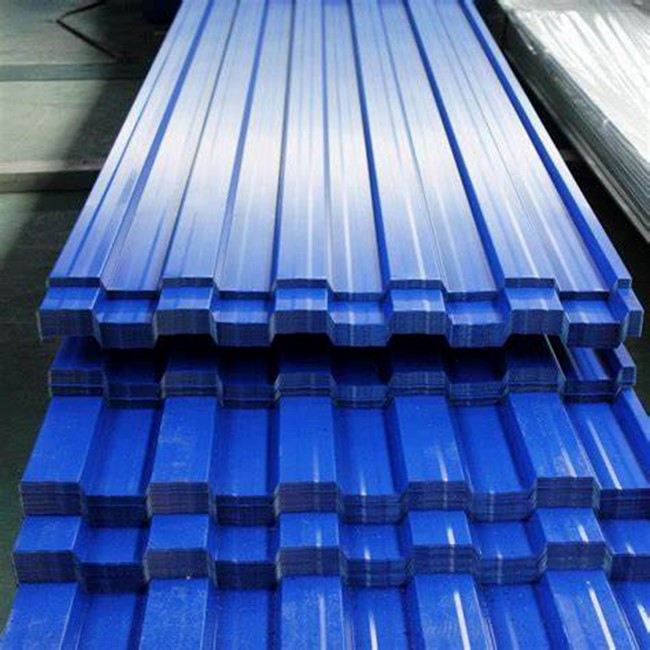

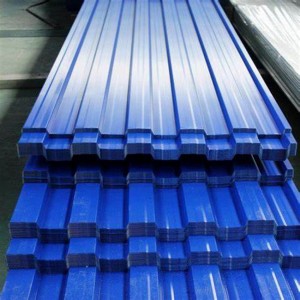

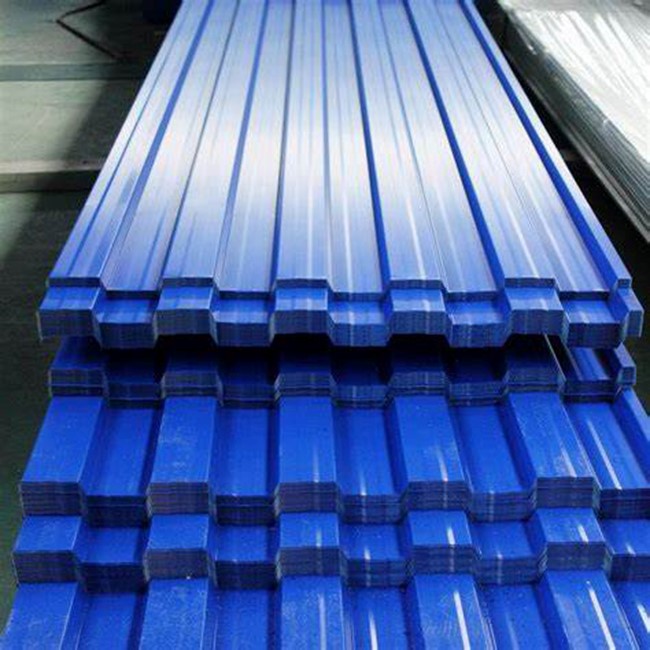

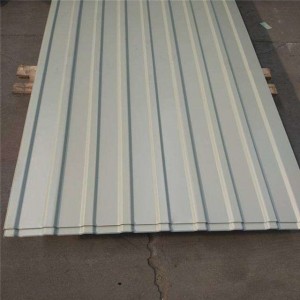

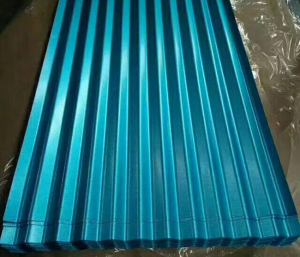

Color pressure tile

The thickness is 0.2-4mm, the width is 600-2000mm, and the length of the steel plate is 1200-6000mm.

The production process

Due to no heating in the production process, there is no hot rolling often occur pitting and oxide iron defects, good surface quality, high finish. Moreover, the size precision of cold-rolled products is high, and the properties and structure of cold-rolled products can meet some special requirements, such as electromagnetic properties, deep drawing properties, etc.

Performance: mainly used low carbon steel, requires good cold bending and welding performance, as well as certain stamping performance.

(1) After annealing, it is processed into ordinary cold rolling;

(2) Galvanizing unit with annealing pre-treatment device processes galvanizing;

(3) Basically do not need to process the panel.

Manufacture volume has a good performance, that is, by cold rolling, the thickness can be thinner, higher precision cold-rolled strip steel and steel plate, high straightness, surface finish, surface clean bright, easy to manufacture plating processing, many varieties, wide application, high stamping performance and no limitation at the same time, the characteristics of low yield point, so the manufacture with a wide range of USES, Mainly used in automobile, printing iron bucket, construction, building materials, bicycles and other industries, but also the best selection of organic coating steel plate production.

Color steel coil is a kind of composite material, also known as color coated steel plate is made of strip steel in the production line after continuous surface degreasing, phosphating and other chemical transfer coating treatment, coated with organic coating by baking products.

Color coil is a kind of composite material, both steel plate and organic materials. Not only the mechanical strength of steel plate and easy molding performance, but also the good decorative organic materials, corrosion resistance.

Color coil coating types can be divided into: polyester (PE), silicon modified polyester (SMP), polyvinylidene fluoride (PVDF), high weather resistance polyester (HDP), clinker sol.

GB/T 12754-2006 Color coated steel plate and strip

GB/T 13448-2006 Color coated steel plate and strip test method

GB 50205-2001 Code for acceptance of construction quality of steel structure engineering

Color steel materials are divided into five categories: packaging, home appliances, building materials, optical materials and decorative materials. Among them, home appliances color steel material technology is the best and the most fine, the highest production requirements

Conventional coatings come in several categories, the most advanced being fluorocarbon, which can last almost 20 years. Generally distributed from steel mills in the form of rollers to various places. The color steel plate we often see refers to the processed plate, the thickness is about 0.2~10mm, it is composed of the middle filler and the color steel plate on both sides. Among them, the color plate thickness has 0.4mm, 0.5mm, 0.6mm and other different thickness, the middle layer can be polyurethane, rock wool or foam plastic. Because there are special profiles, so the factory building with color steel plate construction speed is very fast (such as THE SARS xiaotangshan hospital), but the strength is low. The substrate of color coated steel plate is cold rolled substrate, hot dip galvanized substrate and galvanized zinc substrate. Coating types can be divided into polyester, silicone modified polyester, polyvinylidene fluoride and plastisol. The surface state of colored coated steel plate can be divided into coated plate, embossed plate and printed plate.

Color coated steel plate is widely used in construction appliances and transportation industries, for the construction industry is mainly used for steel structure plant, airport, warehouse and refrigeration and other industrial and commercial building roof walls and doors, civil buildings with less color steel plate.

Other industrial applications are bicycle parts, various welded pipes, electrical cabinets, highway guardrail, supermarket shelves, warehouse shelves, fences, water heater liner, barrel making, iron ladder and stamping parts of various shapes. With the continuous development of economy, zero processing throughout the industry, the rapid development of processing plants mushrooming, the demand for plate greatly increased, but also increased the potential demand for hot rolled pickling plate.