China Factory for Brass Coil - High-Strength Steel Boiler Plate – JINBAICHENG

China Factory for Brass Coil - High-Strength Steel Boiler Plate – JINBAICHENG Detail:

Product Introduction

Standards: Ace, ASTM, bs, GB, JIS, ASTM

Grade: A516 GR70 / Q345R

made in China

Brand Name: Jinbaicheng

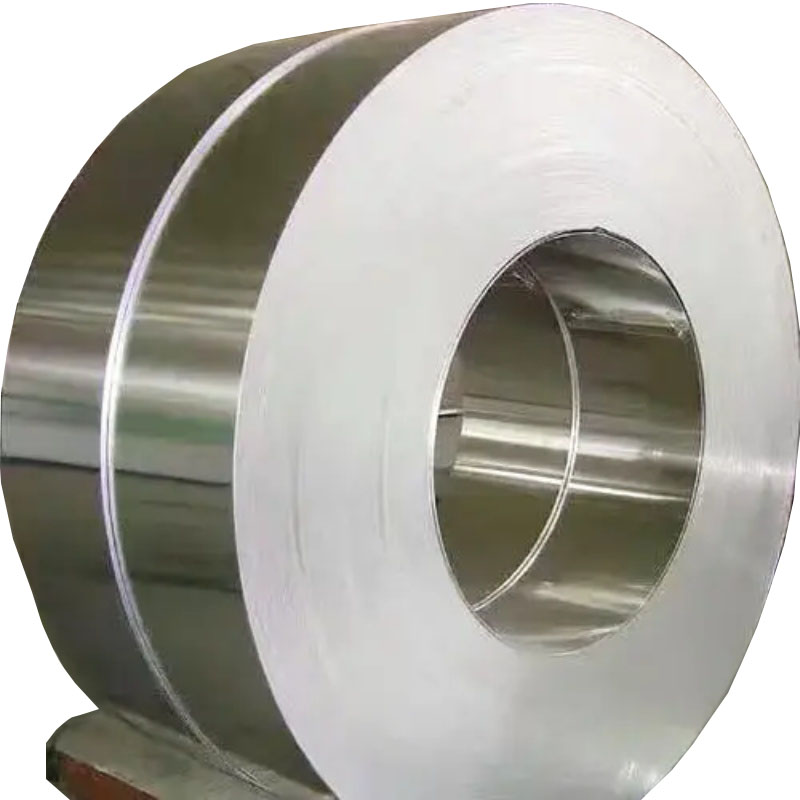

Model: 0.12-2.0mm*600-1250mm

Type: steel plate, boiler plate

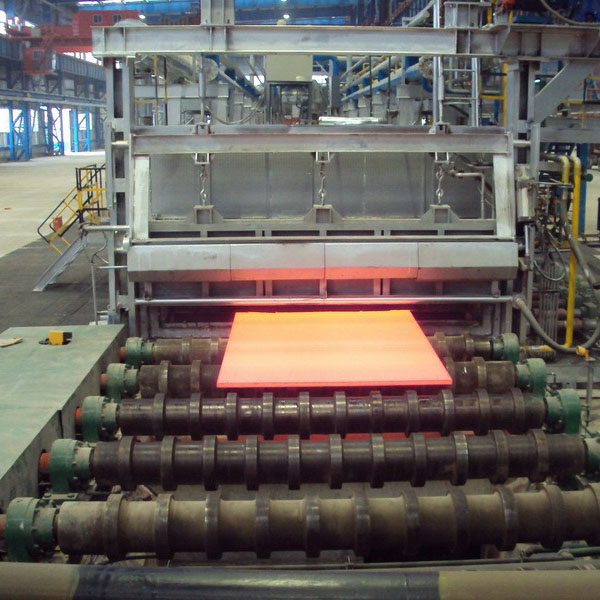

Technology: Hot Rolling

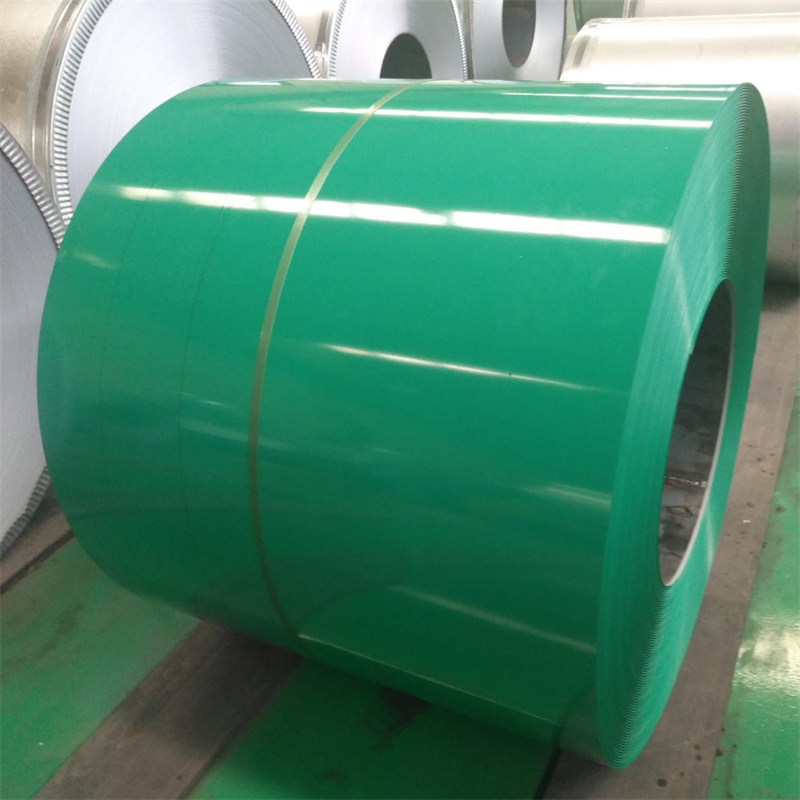

Surface treatment: coating

Application: boiler plate

Special purpose: high-strength steel plate

Width: 600mm-1500mm

Length: required

Tolerance: +5mm

Processing services: bending, welding, uncoiling, cutting, punching

Delivery time: 21 days

Product name: A516 GR70 boiler plate/ASTM A516 70 grade pressure vessel steel plate

Material: A516

Certificate: Significant

Shape: flat material, sheet, coil, plate

Quality: Grade 1 pressure vessel steel

Advantages: stable specifications and accurate dimensions

Packing: Seaworthy export standard

Equivalent results: P265GH SA387 P355N SB450 13CrMo44 15CrMoR

Equivalent specifications: EN, AISI, ASME, DIN, BS, JIS, GB, etc.

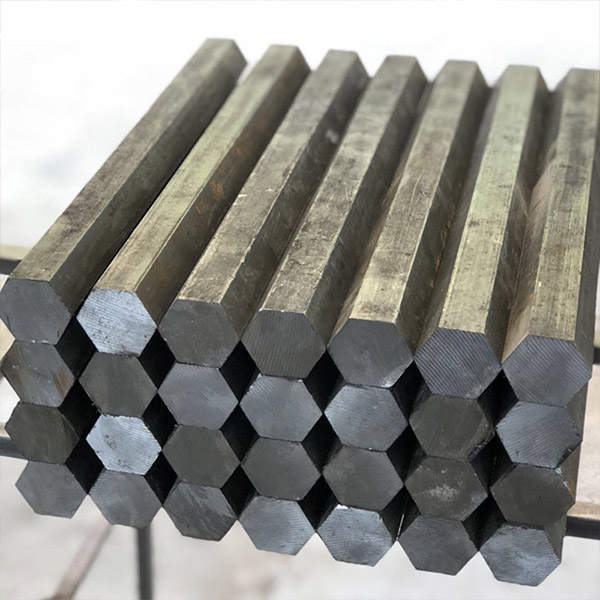

Product Display

Product Category

Automobile steel plates are divided into hot-rolled steel plates, cold-rolled steel plates and coated steel plates according to the characteristics of the production process; from the perspective of strength, they can be divided into: ordinary steel plates (soft steel plates), low-alloy high-strength steel plates (HSLA), and ordinary high-strength steel plates (high Strength IF steel, BH steel, phosphorous steel and IS steel, etc.) and advanced high-strength steel (AHSS), etc.

Purpose deep processing technology

Laser tailor-welded blank and continuous variable cross-section board technology

1. Tailor Welded Blanks (Tailor Welded Blanks, TWB) uses laser as the welding heat source to combine and weld several different materials, different thicknesses, and different coatings of steel, stainless steel, aluminum alloy, etc. into a whole plate.

2. Using laser tailored welding technology, it is possible to reasonably combine materials of different thickness sizes and strength levels according to the stress conditions of the structural parts, improve the structural rigidity while reducing the weight of the parts, and also increase the utilization rate of materials and reduce the number of parts. The number of parts in the simplifies the process. Laser tailored welding technology has become the main technical means of automobile lightweight, and it has been applied to the models of many manufacturers. Mainly used in front and rear door inner panels, front and rear longitudinal beams, side panels, floor panels, A, B, and C pillars on the inside of the door, wheel covers and trunk inner panels, etc.

3. Tailor Rolling Blanks (TRB), also called differential thickness plates, refers to the real-time change of the roll gap size through the computer during the rolling process of the steel plate, so that the rolled thin plate has a pre-determined direction along the rolling direction. Custom variable cross-sectional shape.

4. Continuous variable cross-section panel technology has been widely used in the manufacture of body structure parts, such as engine cover, B-pillar, body chassis, motor spacer guide, middle column inner panel, mudguard and crash box, etc., and has been successfully applied to Audi, BMW, Volkswagen, GM and other models.

5. Laser tailored welding and continuous variable cross-section technology change the thickness of the stamping material through different technological means, and are used to solve the problem of different load-bearing capacity requirements for different parts of auto parts under load. Compared with the two, the advantage of tailor-made laser welding technology lies in its flexibility, which can realize the splicing of any position and the splicing of different materials. The advantage of continuous variable cross-section technology is that there is no welding seam, the hardness change along the length direction is relatively gentle, it has better formability, and the surface quality is good, the production efficiency is high, and the cost is low. Luggage, medical equipment, motorcycle shell; automobile, bus inner roof, dashboard; seat backing, door panel, window frame, etc.

Mechanical behavior

|

Product Name |

Hot Rolled Alloy Water Tank Container Used Steel Boiler Plate a516-70 |

|

Standard |

Astm, Gb, Din, Jis, En, Etc. |

|

Material |

Boiler Steel |

|

Size |

Thickness: 2-300mm |

|

Width: 1000-3000mm |

|

|

Length: 1000~12000mm Or As Required |

|

|

Application |

Building Construction, Bridges, Vehicle Parts, Buttocks, High-Pressure Vessels, Boilers, Large Structural Steels, Etc. |

|

Delivery Status |

Hot Rolling, Controlled Rolling, Normalizing Or As Required |

|

Surface |

Hic, Ssc, Spwht, As Required |

|

Certification |

Bv、Iso、Sgs、Ce … |

|

To Pay |

t/t, l/c, West Union, Etc. |

|

Delivery Time |

15-20 Days After Deposit, Depending On Quantity |

|

Pack |

Standard Shipping Package Or As Required |

Product detail pictures:

Related Product Guide:

Gaining customer satisfaction is our company's aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for China Factory for Brass Coil - High-Strength Steel Boiler Plate – JINBAICHENG , The product will supply to all over the world, such as: Ethiopia, Jamaica, Seattle, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.