Best quality Alloy Pipe - Spiral Welded Pipe – JINBAICHENG

Best quality Alloy Pipe - Spiral Welded Pipe – JINBAICHENG Detail:

Product Introduction

Place of Origin: Shandong, China

Model: PVC straw

Material: PVC

Specification: 3/4″-14″

Length: 10m/20m/30m/50m

Thickness: 3mm-12mm

Standard: ISO

Processing Service: Forming

Color: blue, orange, yellow, red, etc.

Working pressure: 2bar-10bar

Working temperature: -5℃ to +150℃

Features: wear resistance, chemical resistance, impact resistance and extrusion resistance

Conveying medium: liquid, powder, granule

Connection: Camlock, KC connector, hose Mender, Bauer, Storz, Pin Lug

Product name: PVC suction hose blasting

Pressure: 6bar-30bar

Inner diameter: 25mm-356mm

Used for: industry, agriculture and construction

Supply Ability: 120 tons/month

Packing details: CARTON

Port: China

Product Display

Production Process

(1) Raw materials are strip steel coils, welding wires, and fluxes. Strict physical and chemical inspections are required before investment.

(2) Butt joint of strip steel head and tail, adopt single wire or double wire submerged arc welding, after coiling into steel pipe, adopt automatic submerged arc welding to repair welding.

(3) Before forming, the strip undergoes leveling, edge trimming, edge planing, surface cleaning and conveying, and pre-bending treatment.

(4) The electric contact pressure gauge is used to control the pressure of the cylinders on both sides of the conveyor to ensure the smooth conveying of the strip.

(5) Adopt external control or internal control roll forming.

(6) The welding seam gap control device is used to ensure that the welding seam gap meets the welding requirements, and the pipe diameter, the amount of misalignment and the welding seam gap are all strictly controlled.

(7) Both internal welding and external welding adopt American Lincoln electric welding machine for single-wire or double-wire submerged arc welding, so as to obtain stable welding specifications.

(8) The welded seams are all inspected by an online continuous ultrasonic automatic flaw instrument, which guarantees 100% non-destructive testing coverage of spiral welds. If there is a defect, it will automatically alarm and spray the mark, and the production workers can adjust the process parameters at any time according to this to eliminate the defect in time.

(9) Air plasma cutting machine is used to cut the steel pipe into individual pieces.

(10) After cutting into single steel pipes, each batch of steel pipes must undergo a strict first inspection system to check the mechanical properties, chemical composition, fusion status of the welds, the surface quality of the steel pipes and pass non-destructive inspections to ensure that the pipe-making process is qualified. After that, it can be officially put into production.

(11) The parts with continuous sonic flaw detection marks on the weld are re-examined by manual ultrasonic and X-ray. If there is a defect, after repairing, it will go through non-destructive inspection again until it is confirmed that the defect has been eliminated.

(12) The pipes where the strip steel butt welding seams and the D-shaped joints intersecting the spiral welding seams are all inspected by X-ray television or filming.

(13) Each steel pipe undergoes hydrostatic pressure test, and the pressure adopts radial seal. The test pressure and time are strictly controlled by the steel pipe hydraulic microcomputer detection device. The test parameters are automatically printed and recorded.

(14) The pipe end is mechanically processed, so that the verticality of the end face, the bevel angle and the obtuse edge can be accurately controlled.

Standards and classification

Standard

Commonly used standards for spiral pipes are generally divided into: SY/T5037-2018 (Ministry standard, also called spiral seam submerged arc welded steel pipe for ordinary fluid transportation pipelines), GB/T9711.1-1997 (National standard, also called oil and gas industry transportation steel pipe The first part of the technical delivery conditions: Grade A steel pipe (the strict requirements are GB/T9711.2 Grade B steel pipe), API-5L (American Petroleum Institute, also called pipeline steel pipe; which is divided into two grades: PSL1 and PSL2), SY/T5040-92 (Spiral submerged arc welded steel pipe for pile).

Classification

The spiral seam submerged arc welded pipe for pressure-bearing fluid transportation is mainly used for pipelines for transporting oil and natural gas. The steel pipe has strong pressure bearing capacity and good plasticity, which is convenient for welding and processing. Submerged arc welded steel pipes made by submerged arc welding or single-sided welding for general low-pressure fluid transportation such as water, gas, air and steam.

Specification weight table

The calculation formula for the weight of spiral welded pipe: (outer diameter-wall thickness) * wall thickness *0.0246615

| Nominal outer diameter mm | Nominal wall thickness | |||||||||||||||

| 5.0 | 5.5 | 6.0 | 7.0 | 8.0 | 9.0 | 10.0 | 11.0 | 12.0 | 13.0 | 14.0 | 15.0 | 16.0 | 18.0 | 20.0 | 22.0 | |

| 219 | 26.88 | 29.46 | 32.01 | 37.09 | 42.13 | |||||||||||

| 273 | 33.54 | 36.78 | 40.01 | 46.42 | ||||||||||||

| 325 | 39.46 | 43.33 | 47.26 | 54.90 | 62.54 | 70.13 | ||||||||||

| 377 | 45.88 | 50.39 | 54.89 | 63.87 | 72.80 | 81.67 | ||||||||||

| 426 | 51.91 | 57.03 | 62.14 | 72.33 | 82.46 | 92.55 | 102.59 | |||||||||

| 457 | 55.73 | 61.24 | 66.73 | 77.69 | 88.58 | 99.43 | 110.23 | 120.98 | 131.60 | 142.34 | ||||||

| 508 | 74.28 | 86.48 | 98.64 | 110.75 | 122.81 | 134.82 | 146.78 | 158.69 | ||||||||

| 529 | 77.38 | 90.11 | 102.78 | 115.41 | 127.99 | 140.51 | 152.99 | 165.42 | ||||||||

| 559 | 81.82 | 95.29 | 108.70 | 122.07 | 135.38 | 148.65 | 161.87 | 175.04 | ||||||||

| 610 | 89.37 | 104.09 | 118.76 | 133.39 | 147.96 | 162.48 | 176.96 | 191.39 | ||||||||

| 630 | 92.33 | 107.54 | 122.71 | 137.82 | 152.89 | 167.91 | 182.88 | 197.80 | ||||||||

| 660 | 96.77 | 112.72 | 128.63 | 144.48 | 160.29 | 176.05 | 191.76 | 207.42 | ||||||||

| 720 | 105.64 | 123.08 | 140.46 | 157.80 | 175.09 | 192.32 | 209.51 | 226.65 | ||||||||

| 820 | 140.34 | 160.19 | 179.99 | 199.75 | 219.45 | 239.10 | 258.71 | 276.26 | 297.77 | 317.23 | 256.01 | 394.58 | 432.96 | |||

| 914 | 178.74 | 200.06 | 222.93 | 244.95 | 266.92 | 288.84 | 310.72 | 332.54 | 354.31 | 397.74 | 440.95 | 483.96 | ||||

| 920 | 179.92 | 202.19 | 224.41 | 246.58 | 268.70 | 290.77 | 312.79 | 334.76 | 356.68 | 400.40 | 443.91 | 486.13 | ||||

| 1016 | 198.86 | 223.49 | 248.08 | 272.62 | 297.10 | 321.54 | 345.93 | 370.27 | 394.56 | 443.02 | 491.26 | 539.30 | ||||

| 1020 | 199.65 | 224.38 | 249.07 | 273.70 | 298.39 | 322.82 | 347.31 | 371.75 | 396.14 | 44.79 | 493.23 | 541.47 | ||||

| 1220 | 296.39 | 327.95 | 357.47 | 386.94 | 416.36 | 445.73 | 475.58 | 533.58 | 591.88 | 649.98 | ||||||

| 1420 | 347.71 | 362.21 | 416.66 | 451.06 | 485.41 | 519.71 | 553.96 | 622.36 | 690.52 | 758.49 | ||||||

| 1620 | 397.03 | 436.46 | 475.84 | 515.17 | 554.46 | 593.60 | 632.87 | 711.14 | 789.17 | 867.00 | ||||||

| 1820 | 446.35 | 490.71 | 535.02 | 579.29 | 623.50 | 667.67 | 711.79 | 799.92 | 887.81 | 975.51 | ||||||

| 2020 | 495.67 | 544.96 | 594.21 | 643.40 | 692.55 | 741.65 | 796.70 | 888.70 | 986.46 | 1084.21 | ||||||

| 2220 | 544.99 | 599.21 | 653.39 | 707.52 | 761.60 | 815.63 | 869.61 | 977.48 | 1085.11 | 1192.5 | ||||||

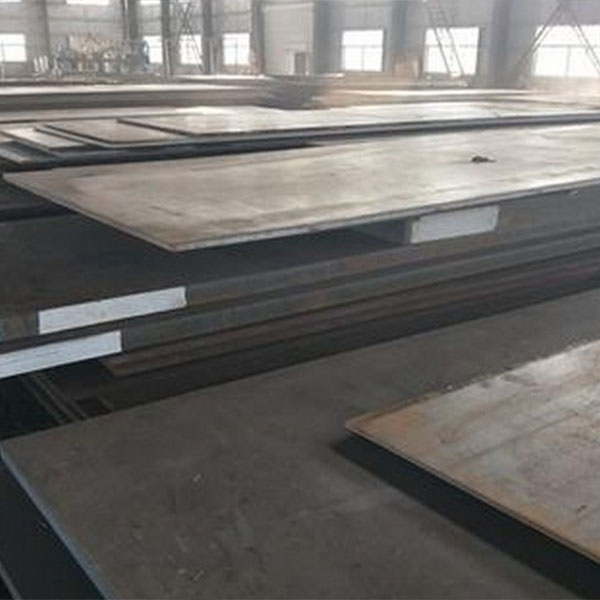

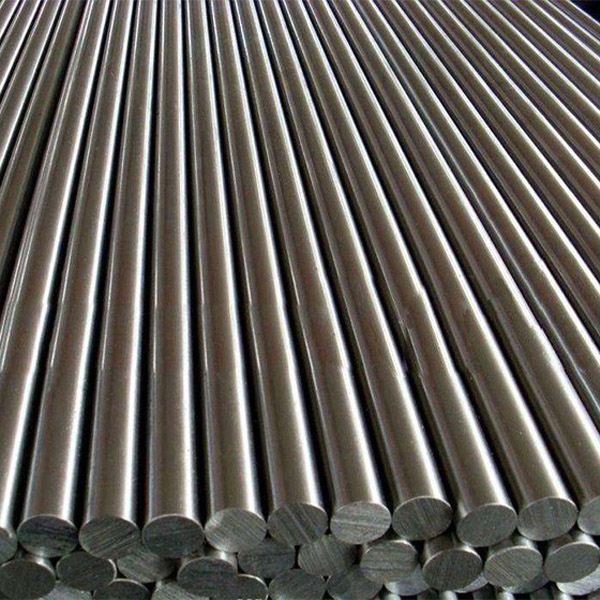

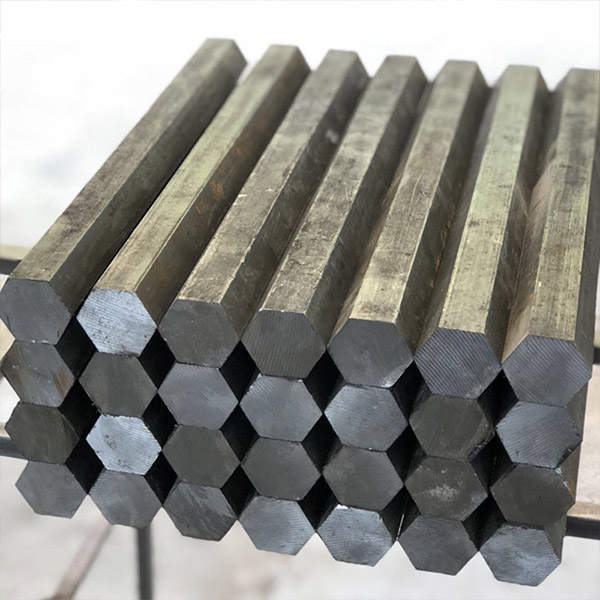

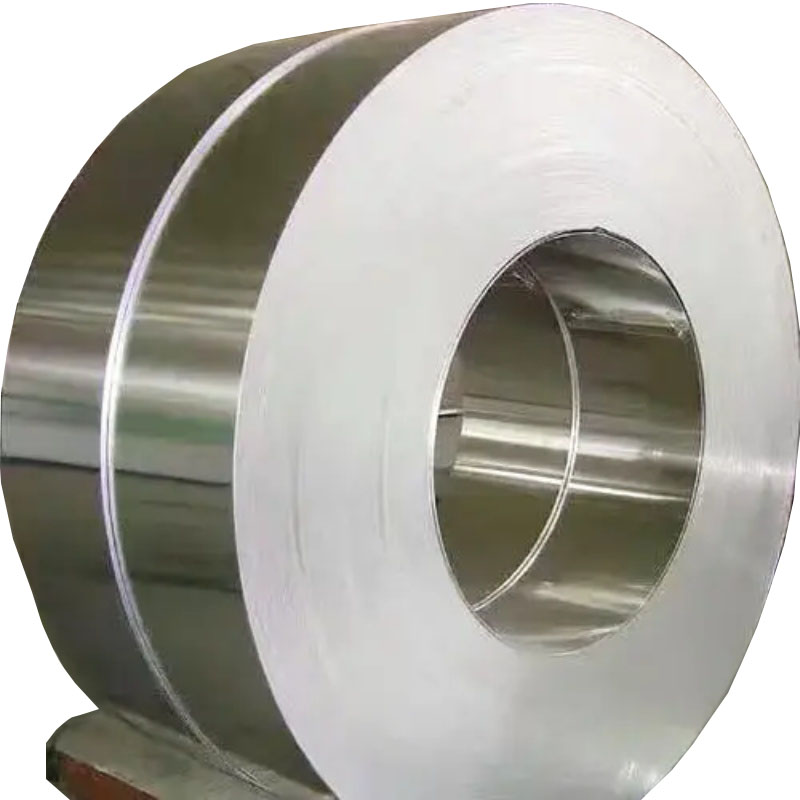

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Best quality Alloy Pipe - Spiral Welded Pipe – JINBAICHENG , The product will supply to all over the world, such as: Italy, Czech republic, Norway, For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.