API 7-1Non-Magnetic Drill Collars for Well Drilling

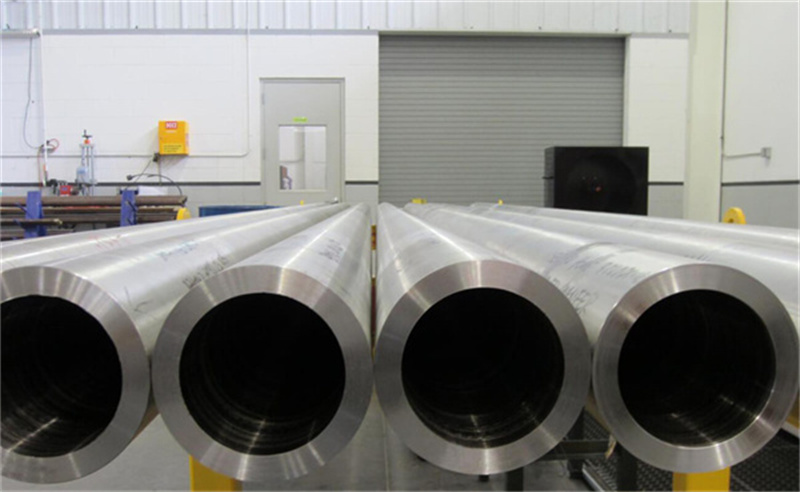

Drill collars are thick-wall tubulars machined from solid steel bars and manufactured to specifications to meet and/or exceed API specifications. Our experience in materials specification, mechanical properties, heat treatment, machining and inspection are reflected in our product performance. Drill collars come in slick and spiral designs with additional features for safe and trouble-free operations.

| Element | P530 P530 HS |

P550 | P580 | P750 | P750I |

| Carbon | max. 0.05 | max. 0.06 | max. 0.06 | max. 0.03 | max. 0.03 |

| Manganese | 18.50-20.00 | 20.00-21.60 | 22.00-24.50 | 1.50-3.00 | 1.50-3.00 |

| Chromium | 13.00-14.00 | 18.30-20.00 | 22.00-24.50 | 26.50-29.50 | 26.50-29.50 |

| Molyddenum | 0.40-0.60 | min. 0.50 | max. 1.50 | 2.00-4.00 | 2.00-4.00 |

| Nitrogen | 0.25-0.40 | min. 0.60 | max. 0.75 | min. 0.20 | min. 0.20 |

| Nickel | max. 1.50 | min. 2.00 | max. 2.50 | 28.00-31.50 | 28.00-31.50 |

* P530 HS Compared with P 530 shows higher yield strength

* HS (High strength)

| Element | P530 | P530 HS | P 550 | P 580 | P750 | P750 I* |

| Yield strength min KSI 3 1/2 to 6 7/8 OD 7″ to 11″ OD |

110 100 |

120 110 |

140 130 |

140 130 |

140 130 |

min 155 |

| Tensile strength KSI 3 1/2 to 6 7/8 OD 7″ to 11″ OD |

120 120 |

130 130 |

150 150 |

150 150 |

150 150 |

min 160 |

| Elongation min % 3 1/2 to 6 7/8 OD 7″ to 11″ OD |

25 25 |

25 25 |

20 20 |

20 20 |

15 15 |

10 10 |

| Reduction of area min. % | 50 | 50 | 50 | 50 | 50 | 50 |

| Impact energy min. ft. lb. | 90 | 90 | 60 | 60 | 100 | 80 |

| Hardness – Brinell | 260-350 | 285-365 | 300-430 | 350-450 | 300-400 | 300-410 |

| Endurance strength min. KSI/N=107 /N=105 |

– – |

+/-50 +/-60 |

+/-60 +/-80 |

+/-60 +/-80 |

+/-60 +/-80 |

* Applicable only for dimensions up to OD = max. 5,5 inches Sampling: 1″ below surface

The reputation of JINBAICHENG in the manufacture and supply of Non-Mag drill string components is based upon extensive in-house experience both in metallurgy and precision manufacturing. JINBAICHENG has always been the leader in the development of Non-Mag materials, special manufacturing processes and testing procedures such as hammer peening and hot-spot testing.