35CRMO Is Alloy Structural Steel

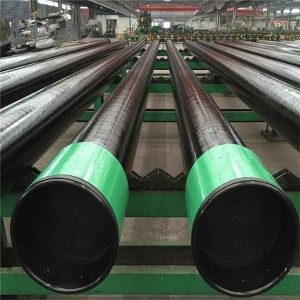

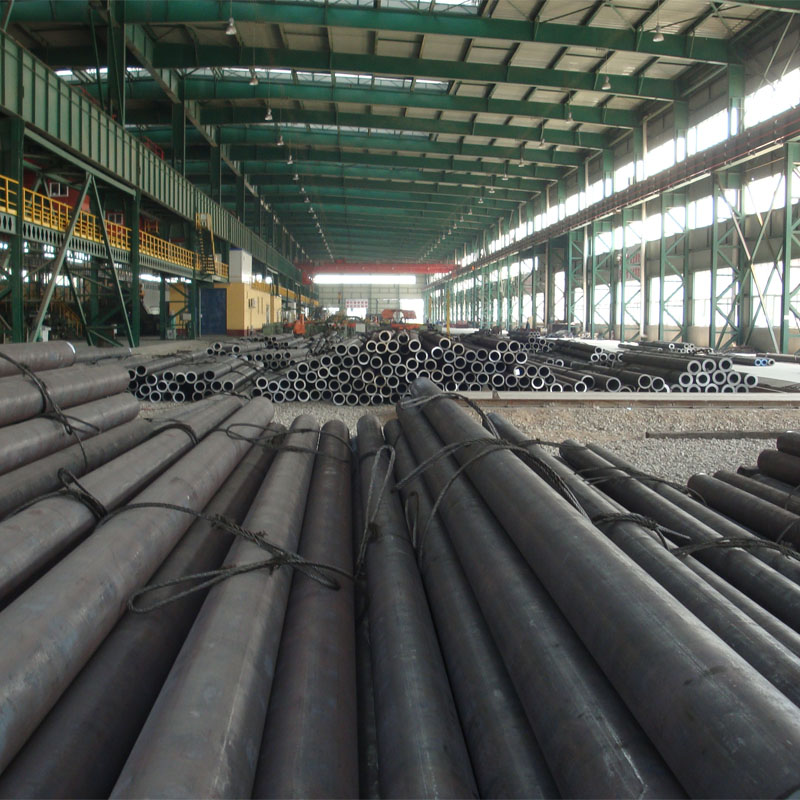

It is used to manufacture important parts in various machines that bear impact, bending and torsion, and high loads, such as rolling mill herringbone gears, crankshafts, hammer rods, connecting rods, fasteners, steam turbine engine main shafts, axles, engine transmission parts, Large motor shafts, perforators in petroleum machinery, bolts for boilers with operating temperature below 400 degrees Celsius, nuts below 510 degrees Celsius, seamless thick-walled pipes for high pressure in chemical machinery (temperature 450 to 500 degrees Celsius, no corrosive media ), etc.; it can also be used instead of 40CrNi to manufacture high-load drive shafts, steam turbine engine rotors, large section gears, supporting shafts (diameter less than 500MM), etc.; process equipment materials, pipes, welding materials, etc.

Used as important structural parts that work under high loads, such as transmission parts of vehicles and engines; rotors, main shafts, heavy-duty transmission shafts, large-section parts of turbo-generators.

35CrMo alloy structural steel (alloy quenched and tempered steel) unified digital code: A30352 Executive standard: GB/T3077-2015

Italy: 35crmo4

NBN: 34crmo4

Sweden: 2234

Japanese standard: SCM432/SCCrM3