316 And 317 Stainless Steel Wire

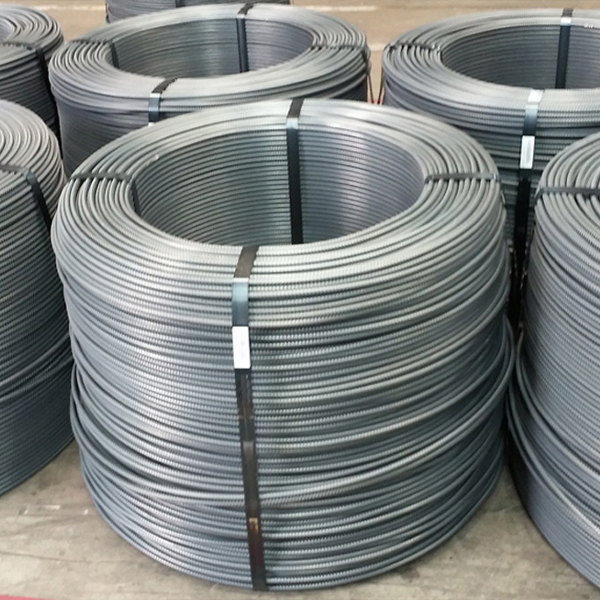

Stainless steel wire drawing (stainless steel wire drawing): a metal plastic processing process in which a wire rod or a wire blank is drawn from a die hole of a wire drawing die under the action of a drawing force to produce a small-section steel wire or a non-ferrous metal wire. Wires with different cross-sectional shapes and sizes of various metals and alloys can be produced by drawing. The drawn wire has precise dimensions, smooth surface, simple drawing equipment and molds, and easy manufacturing.

The stress state of wire drawing is the three-dimensional principal stress state of two-way compressive stress and one-way tensile stress. Compared with the principal stress state where all three directions are compressive stress, the drawn metal wire is easier to reach the state of plastic deformation. The deformation state of drawing is a three-way main deformation state of two-way compression deformation and one tensile deformation. This state is not good for the plasticity of metal materials, and it is easier to produce and expose surface defects. The amount of pass deformation in the wire drawing process is limited by its safety factor, and the smaller the amount of pass deformation, the more the drawing passes. Therefore, multiple passes of continuous high-speed drawing are often used in the production of wire.

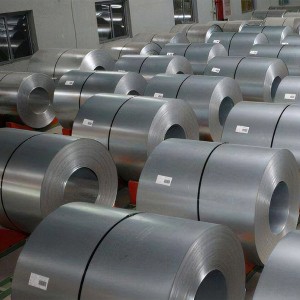

Generally, it is divided into 2 series, 3 series, 4 series, 5 series and 6 series stainless steel according to austenitic, ferritic, two-way stainless steel and martensitic stainless steel.

316 and 317 stainless steel (see below for the properties of 317 stainless steel) are molybdenum-containing stainless steels. The content of molybdenum in 317 stainless steel is slightly higher than that of 316 stainless steel. Due to the molybdenum in steel, the overall performance of this steel is better than 310 and 304 stainless steel. Under high temperature conditions, when the concentration of sulfuric acid is lower than 15% and higher than 85%, 316 Stainless steel has a wide range of uses. 316 stainless steel also has good resistance to chloride corrosion, so it is usually used in marine environments. 316L stainless steel has a maximum carbon content of 0.03, which can be used in applications where annealing cannot be carried out after welding and maximum corrosion resistance is required