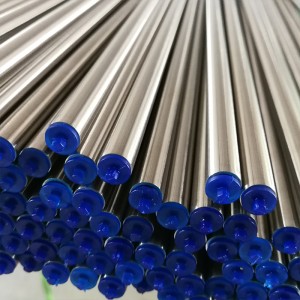

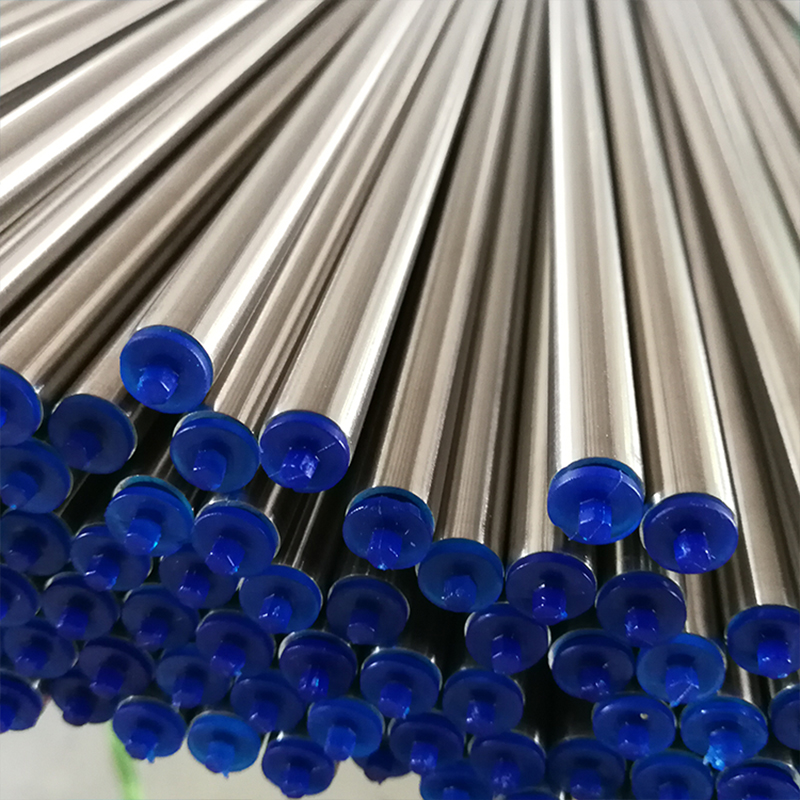

304 316 Mirror Polished Seamless Stainless Steel Pipe

Standard: JIS

made in China

Brand Name: Jinbaicheng

Model: 304 316 309S 316L 321

Type: Seamless steel

Grade: 304 316 309S 316L 321, 316Ti, 316L, 316, 321, 304, Application, 3304L

Industry, fertilizer pipe welding line

Type: Seamless

Outer diameter: 25.4mm

Tolerance: ±1%

Processing services: bending, welding, uncoiling, punching, cutting, forming, customization

Grade: 304 316 309S 316L 321

Section shape: round

Alloyed or not: non-alloyed

Surface treatment: BA

Invoice: According to theoretical weight

Delivery time: 15-21 days

Product name: 304 316 mirror polished seamless stainless steel pipe/tube

Shape: round, square, rectangular

Technology: Hot rolled and cold drawn

Surface: bright/picked/polished

Payment terms: 30% TT Advance + 70% Balance Price Term: CIF CFR FOB EX-WORK MOQ: 1 ton

Packaging: Standard airworthy packaging

Sample: free of charge

Inventory: Abundant

Certification: BV

Supply Ability: 10,000 tons/ton per month

Packing details: ordinary packing

Port: Shanghai Tina Jingua Hangzhou Qingdao

| Stainless steel pipe specification table | ||

| Specification | Specification | Specification |

| 6-12×1.5-2.5 | 73×4-4.5-5-6-7-8-9-10-12-15 | 219×30-40 |

| 14×1.5-2.5-3 | 76×4-4.5-5-6-7-8-9-10-12-14 | 245×8-10-14-17-20-22 |

| 16×1.5-2.5-4 | 83×4.5-5-10 | 245×25-28-30-34-40 |

| 18×2.3-4-5 | 89×4.5-8-10 | 273×7-9-12-15-18-20-25 |

| 20×2.5-3-5 | 95×4.5-6-8 | 273×30-35-38-40 |

| 24×2.5-3-4-5-6 | 102×4.5-5-6-10-12-14-16-20 | 299×8-12-16-20-24-28 |

| 25×2.5-3-4-5-6 | 108×4.5-5-14-18-20-22 | 299×30-32-36-38-40 |

| 28×3-3.5-4-5-6 | 114×4.5-5-6-7-8-10-12-14-18-20 | 325×8-12-14-18-38 |

| 32×3.5-4-5-6-8 | 121×4.5-5-6-7-8-10-12-14-16-20 | 325×28-32-34-38 |

| 34×4-5-6-8 | 127×4.5-5-6-7-8-10-12-14-16-20 | 351×10-16-20-25-40 |

| 36×3.5-5-6-8 | 133×4.5-6-8-12-14-16-18-20-25-30 | 355×6-18-20-25-30-40 |

| 38×4-5-6-7-8-9-10 | 140×5-6-7-8-9 | 377×8-12-15-20-24-28 |

| 39×3.5-5-8-10 | 146×4.5-6-8 | 377×30-37-40 |

| 42×3.5-4-5-6-7-8-9-10 | 152×4.5-6- | 402×10-20-25-30-35 |

| 45×3.5-4-5-6-7-8-9 | 159×4.5-6-10-12-14 | 406×10 |

| 48×3.5-4-5-6-7-8-9-10 | 159×16-18 | 426×10 |

| 51×3.5-4-5-6-7-8-9-10 | 168×8-25-30-35 | 450×10-20-25-34-40 |

| 56×3.5-4-5-6-7-8-9-10 | 180×8-12-16-25-30 | 480×25-30-40 |

| 57×3.5-5-6-7-8-9-10-12 | 180×32-34-38-40 | 500×10-34-40-45 |

| 60×3.5-4.5-5-6-7-8-9-12-14 | 194×6-8-25-30-40 | 510×10-25-34-40-45 |

| 63×3.5-4.5-5-6-7-8-9-10-12-14 | 203×6-7-10-15-20-25-30 | 530×20-30-40 |

| 68×4-4.5-5-6-7-8-9-10-12-14-16 | 203×32-36-40 | 560-720*6-10-24-45 |

| 70×4-4.5-5-6-7-8-9-10-12-15-16 | 219×6-8-12-16-18-20-25 | |

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| SUS304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0-10.0 | 18/20 | -- | -- |

| SUS301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 6.0-8.0 | 16/18 | -- | -- |

| SUS201 | ≤0.15 | ≤0.75 | ≤5.5/7.5 | ≤0.06 | ≤0.030 | 0.8-1.2 | 16/18 | -- | -- |

| SUS430 | ≤0.12 | ≤0.750 | ≤1.00 | ≤0.040 | ≤0.030 | ≤0.60 | 16/18 | -- | -- |

| SUS443 | ≤0.015 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.030 | -- | ≥20 | -- | ≤0.3 |

| SUS310S | ≤0.1 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.03 | 19-22 | 24-26 | -- | |

| SUS316L | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.30 | 10-14 | 16-18.5 | 2.0-3.0 | -- |

The production process of stainless steel seamless pipe:

a. Round steel preparation;

b. heating;

c. Hot rolled perforation;

d. Cut head

e. Pickling

f. Grinding

g. lubricating;

h. Cold rolling

i. Degreasing

j. Solution heat treatment;

k. Straighten

l. Cut tube

m. Pickling

n. Product testing.

Auto Industry

Stainless steel is mainly used in the exhaust system, which accounts for more than 1/2 of the total amount of automotive stainless steel, and 80% is ferritic stainless steel. The exhaust gas generated by the automobile engine finally flows out of the muffler through the exhaust gas intake pipe, front pipe, hose, converter, and center pipe. Commonly used steel grades for exhaust systems are 409L, 436L, etc. Automobile mufflers mainly use stainless steel welded pipes. According to estimates, stainless steel pipes used in automobiles account for about 1.5% of the entire downstream consumption of stainless steel pipes, and the use ratio of stainless steel seamless pipes and welded pipes is about 2:1.

The petrochemical industry includes the fertilizer industry

There is a huge demand for stainless steel pipes. The industry mainly uses stainless steel seamless pipes. The specifications include: 304, 321, 316, 316L, 347, 317L, etc. The outer diameter is about ¢18-¢610, and the wall thickness is 6mm-50mm Around (usually select medium and low pressure conveying pipes with specifications above Φ159mm), the specific application areas are: furnace pipes, material conveying pipes, heat exchanger pipes, etc.

Transportation of fluids such as water and gas

Stainless steel pipes and their water delivery equipment are the most advanced basic water purification materials in the world today. They have strong corrosion resistance and cannot be compared with cast iron pipes, carbon steel pipes, and plastic pipes.

The best choice for water industry such as water preparation, storage, transportation, purification, regeneration, and desalination. The annual demand is about 25,000 tons.

Equipment manufacturing and maintenance

The annual consumption of stainless steel pipe is more than 20,000 tons. This type of industry mainly uses sanitary or antibacterial grade stainless steel pipes. The sanitary seamless pipe made of imported SUS304 and 316L can meet the special requirements of various media in the food and biopharmaceutical fields. Antibacterial stainless steel has the advantages of stainless steel and good antibacterial properties. The demand for kitchen equipment, workbenches and utensils in the food industry, medical equipment, tableware and towel holders in daily life, and brackets for refrigerated cabinets is increasing.