2021 wholesale price Galvanized Steel Pipe - Cold Galvanized Steel Pipe, Hot-Dip Galvanized Steel Pipe – JINBAICHENG

2021 wholesale price Galvanized Steel Pipe - Cold Galvanized Steel Pipe, Hot-Dip Galvanized Steel Pipe – JINBAICHENG Detail:

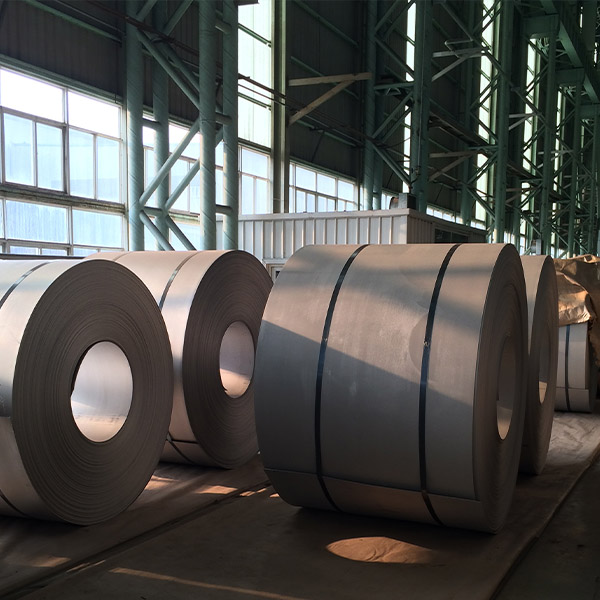

Different galvanized steel pipes

1. Pre-galvanized: Pre-galvanized steel pipe is directly processed from hot-dip galvanized steel strip.

Galvanized layer: 40-60g/sm, if more galvanized layer is needed, it can be processed according to order. (The thickness is 0.7mm-4.5mm)

2. Hot-dip galvanized: Hot-dip galvanized pipe has a thicker zinc coating than pre-galvanized pipe. The black steel pipe will be immersed in a zinc bath for galvanizing. The zinc coating can be: 200-500g/sm

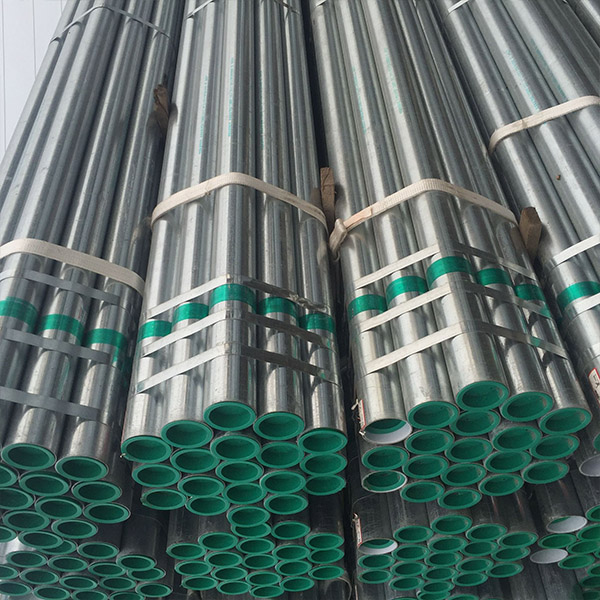

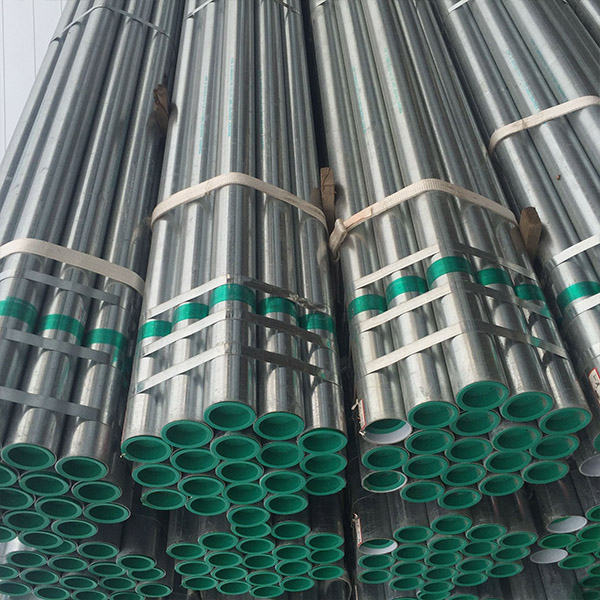

Product Display

skills requirement

The process flow is: black tube-alkaline washing-water washing-pickling-water rinsing-soaking aid-drying-hot dip galvanizing-external blowing-internal blowing-air cooling-water cooling -Passivation-water rinsing-inspection-weighing-storage.

skills requirement

1. Brand and chemical composition

The grade and chemical composition of the steel for galvanized steel pipes should comply with the grade and chemical composition of the steel for black pipes as specified in GB/T3091.

2. Manufacturing method

The manufacturing method of the black pipe (furnace welding or electric welding) is selected by the manufacturer. Hot-dip galvanizing is used for galvanizing.

3. Thread and pipe joints

(A) For galvanized steel pipes delivered with threads, the threads should be machined after galvanizing. The thread should comply with YB 822 regulations.

(B) Steel pipe joints should comply with YB 238; malleable cast iron pipe joints should comply with YB 230.

4. Mechanical properties The mechanical properties of steel pipes before galvanizing should meet the requirements of GB 3091.

5. The uniformity of the galvanized layer Galvanized steel pipe should be tested for the uniformity of the galvanized layer. The steel pipe sample shall not turn red (copper-plated color) after being immersed in copper sulfate solution for 5 consecutive times.

6. Cold bend test The galvanized steel pipe with a nominal diameter of not more than 50mm should be subjected to a cold bend test. The bending angle is 90°, and the bending radius is 8 times the outer diameter. There is no filler during the test, and the weld of the sample should be placed on the outside or upper part of the bending direction. After the test, there should be no cracks and peeling of the zinc layer on the sample.

7. Water pressure test The water pressure test should be carried out in the clarinet. Eddy current flaw detection can also be used instead of the water pressure test. The test pressure or the size of the comparison sample for eddy current testing shall meet the requirements of GB 3092. The mechanical properties of steel is an important index to ensure the final use performance (mechanical properties) of the steel.

Shandong Jinbaicheng Metal Material Co., Ltd. is located in Shandong, the world’s largest welded pipe production base. After years of hard work, a diversified investment development pattern has been formed. In accordance with the requirements of new industrialization, we give full play to our advantages to achieve scale, structure, and quality. Comprehensive improvement of benefits.

We specialize in selling galvanized steel pipes, hot-rolled steel pipes, seamless pipes,. After several years of development, we have established a long-term

Cooperate with customers from more than 70 countries around the world, including Canada, Australia, Singapore, Thailand, South Korea, Vietnam, Mexico, Chile, Peru, and New Zealand. The annual output is 700,000 tons.

Connection method

Galvanized steel pipe connection method: threaded, welded.

Roll groove connection

(1) Cracking of roll groove weld

1. Smooth the inner wall welding ribs of the pressure groove part of the nozzle to reduce the resistance of the rolling groove.

2, Adjust the axis of the steel pipe and the rolling grooving equipment, and require the steel pipe and the rolling grooving equipment to be level.

3. Adjust the groove pressing speed, and the groove forming time can not exceed the stipulation, apply force evenly and slowly.

(2) Roll groove steel pipe fracture

1. Smooth the inner wall welding ribs of the pressure groove part of the pipe mouth to reduce the resistance of the rolling groove.

2, Adjust the axis of the steel pipe and the rolling grooving equipment, requiring the steel pipe and the rolling grooving equipment to be level.

3. Adjust the pressing speed, the pressing speed cannot exceed the stipulation, apply force evenly and slowly.

4. Check the width and model of the support roller and pressure roller of the rolling groove equipment, and check whether there is a mismatch in the size of the two rollers, which may cause seizure.

5. Use a vernier caliper to check whether the groove of the steel pipe is specified.

(3) The groove formed by the rolling groove machine should meet the following requirements

1, The surface of the pipe end to the groove section should be smooth and free of unevenness and roll marks.

2, The center of the groove should be concentric with the pipe wall, the width and depth of the groove should meet the requirements, and check whether the clamp part type is correct.

3. Apply lubricant on the rubber sealing ring and check whether the rubber sealing ring is damaged. The lubricant must not be oil lubricant.

Welded connection

1. The pipe mouth of the galvanized steel pipe is not in a straight line and there is a problem with the oblique mouth of the steel pipe after butting. It is recommended to cut off the pipe head for a short period of time before processing.

2, After the galvanized steel pipe nozzles are connected, the two nozzles are not tightly connected, resulting in uneven thickness of the welded joint; and the pipe is elliptical due to its own reasons or transportation bumps. It is recommended to cut off the pipe head for a short period of time. Process again.

3. After the nozzles of galvanized steel pipes are butted, blisters appear at the nozzles:

4. Due to technical reasons during welding.

5. There are zinc nodules in the nozzle, which can cause welding difficulties and blisters. If the zinc nodules are too large and too many pipes, simple zinc nodules should be removed.

Wire connection

1, Threaded buckle: The pipe hoop and the threaded buckle can not be completely contacted, loosen, cut off the random buckle part, and re-install the thread.

2. The steel pipe thread and the pipe hoop thread do not match and cannot be connected. The pipe hoop should be replaced or the equipment should be adjusted and re-threaded.

3. Missing print after the steel pipe is threaded: Measure whether the wall thickness of the steel pipe can meet the standard thickness requirements of the threaded pipe

Specification

| Type | En10210 galvanized steel pipe |

| Grade | S235jrh(1.0039), s275j0h(1.0149), s275j2h(1.0138), s355j0h(1.0547), s355j2h(1.0576), s355k2h(1.0512), s27(1.0512), 5.9(1.0512), 7(9), 7(9), 5.9(1.0512), s27(1.0512), s27(1.0149), s275j2h(1.0138), s355j0h(1.0547) s(1.0597)h, s355n) s420nh(1.8750), s420nlh(1.8751), s460nh(1.8953), s460nlh(1.8956), s235jrh(1.0039), s275j(1.8750), s420nlh(1.8751), s460nh(1.8953), s235jrh(1.0039), s275j5(j5h), 5j5(04j), 5h(1.8751), 5h(1.8751), s460nh(1.8953) 1.051), s355j2h2(1.0552), s355j2h(1.0552)(1.0493), s275nlh(1.0497), s355nh(1.0539), s355nlh(1.0549), s420nh(1.8750), s420nlh(1.8751), s460nh(1.8953), s460nlh(1.8956) , s275mh(1.8453)(m843)s275ml (s355mlh(1.8846)s420mh(1.8847)s420mlh(1.8848)s460mh(1.8849)s460mlh(1.8850) |

| Thickness | 3mm – 30mm |

| Certification | Ul api |

| Processing service | Bending, welding, uncoiling, punching, cutting |

| Product name | Seamless steel pipe |

| Shape | Round square. Rectangle |

| Length | 3-12m |

| Moq | 1 ton |

| Technology | Hot rolled cold rolled |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for 2021 wholesale price Galvanized Steel Pipe - Cold Galvanized Steel Pipe, Hot-Dip Galvanized Steel Pipe – JINBAICHENG , The product will supply to all over the world, such as: Ghana, Egypt, Bulgaria, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.