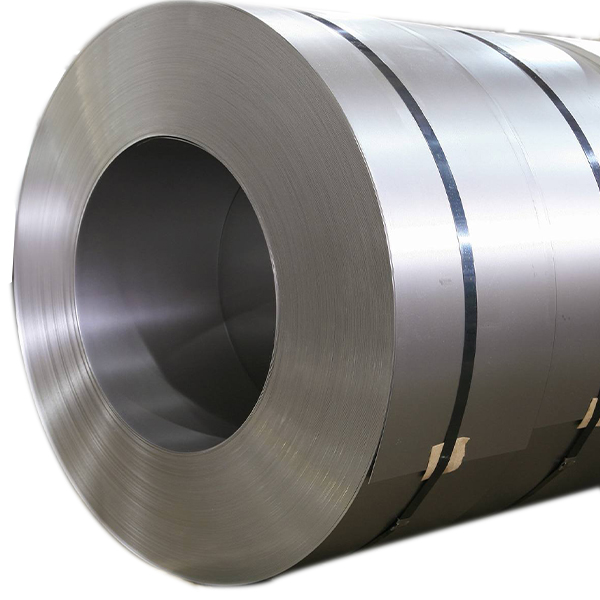

2021 High quality Stainless Steel Cold Rolled Coil - Low Alloy Boiler Steel Plate – JINBAICHENG

2021 High quality Stainless Steel Cold Rolled Coil - Low Alloy Boiler Steel Plate – JINBAICHENG Detail:

material type

Low-alloy steel

Alloy steel is divided into low-alloy steel, medium-alloy steel and high-alloy steel. As the name suggests, they are distinguished by the total amount of alloying elements. The total amount is less than 3.5% is called low-alloy steel, and 5-10% is medium-alloy steel. More than 10% is high alloy steel. In the domestic custom, carbon steel and alloy steel of special quality are called special steel. 31 special steel enterprises across the country specialize in producing this kind of steel, such as high-quality carbon structural steel, alloy structural steel, carbon tool steel, and alloy tools. Steel, high-speed tool steel, carbon spring steel, alloy spring steel, bearing steel, stainless steel, heat-resistant steel, electrical steel, including high-temperature alloys, corrosion-resistant alloys and precision alloys, etc.

use

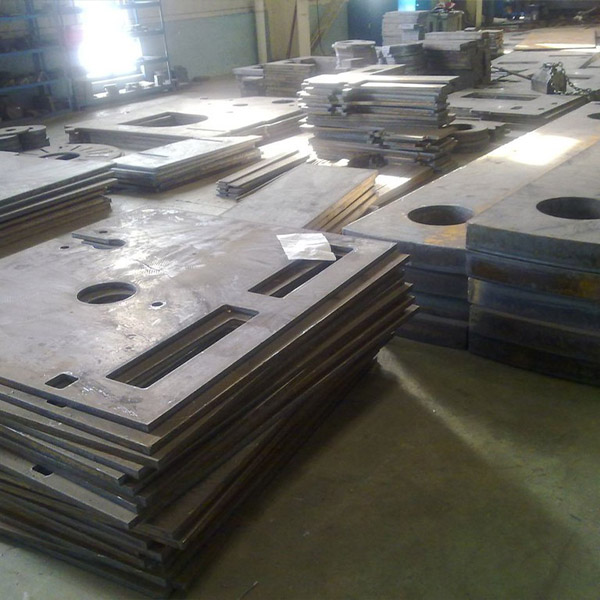

Mainly used in the manufacture of bridges, ships, vehicles, boilers, high-pressure vessels, oil and gas pipelines, large steel structures, etc.

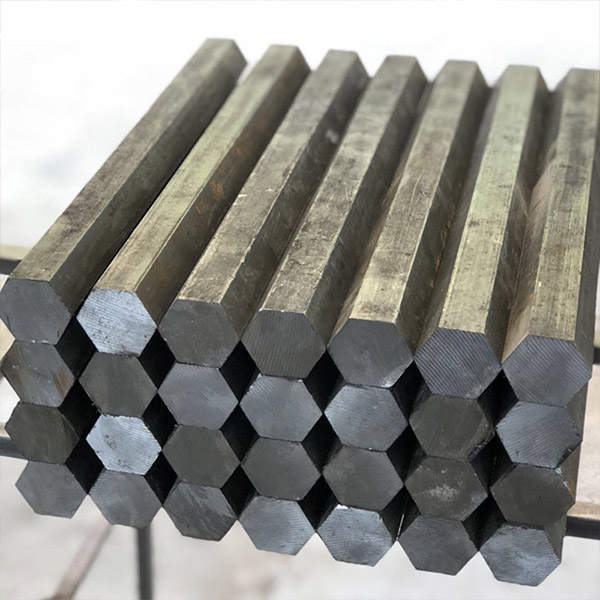

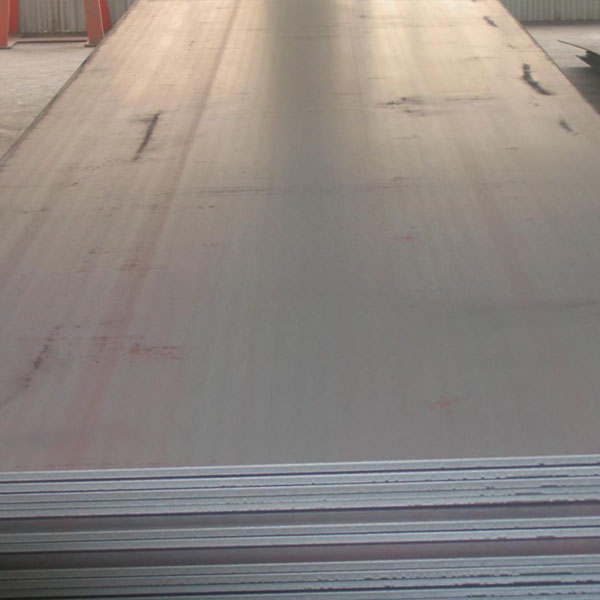

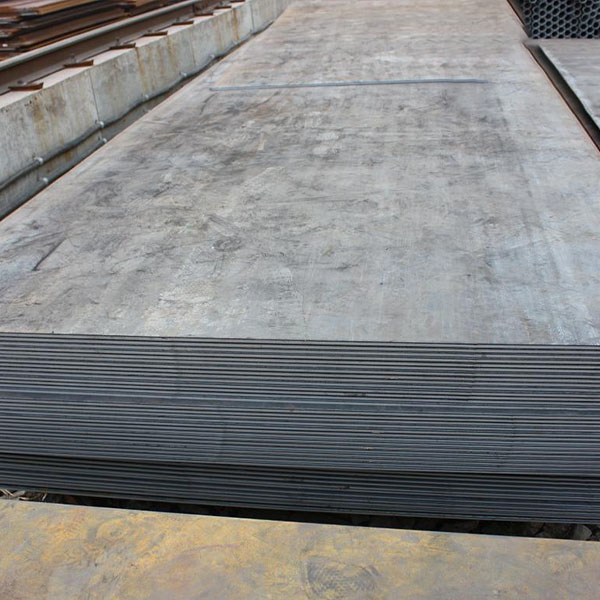

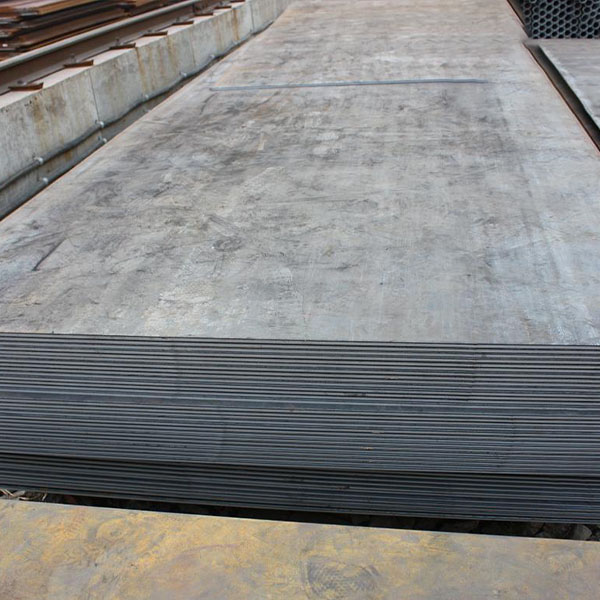

Product Display

characteristic

Performance

(1) High strength: Generally its yield strength is above 300MPa;

(2) High toughness: The elongation is required to be 15%-20%, and the room temperature impact toughness is greater than 600kJ/m~800kJ/m. For large welded components, higher fracture toughness is also required;

(3) Good welding performance and cold forming performance;

(4) Low cold brittle transition temperature;

(5) Good corrosion resistance.

Purpose deep processing technology

Laser tailor-welded blank and continuous variable cross-section board technology

1. Tailor Welded Blanks (Tailor Welded Blanks, TWB) uses laser as the welding heat source to combine and weld several different materials, different thicknesses, and different coatings of steel, stainless steel, aluminum alloy, etc. into a whole plate.

2. Using laser tailored welding technology, it is possible to reasonably combine materials of different thickness sizes and strength levels according to the stress conditions of the structural parts, improve the structural rigidity while reducing the weight of the parts, and also increase the utilization rate of materials and reduce the number of parts. The number of parts in the simplifies the process. Laser tailored welding technology has become the main technical means of automobile lightweight, and it has been applied to the models of many manufacturers. Mainly used in front and rear door inner panels, front and rear longitudinal beams, side panels, floor panels, A, B, and C pillars on the inside of the door, wheel covers and trunk inner panels, etc.

3. Tailor Rolling Blanks (TRB), also called differential thickness plates, refers to the real-time change of the roll gap size through the computer during the rolling process of the steel plate, so that the rolled thin plate has a pre-determined direction along the rolling direction. Custom variable cross-sectional shape.

4. Continuous variable cross-section panel technology has been widely used in the manufacture of body structure parts, such as engine cover, B-pillar, body chassis, motor spacer guide, middle column inner panel, mudguard and crash box, etc., and has been successfully applied to Audi, BMW, Volkswagen, GM and other models.

5. Laser tailored welding and continuous variable cross-section technology change the thickness of the stamping material through different technological means, and are used to solve the problem of different load-bearing capacity requirements for different parts of auto parts under load. Compared with the two, the advantage of tailor-made laser welding technology lies in its flexibility, which can realize the splicing of any position and the splicing of different materials. The advantage of continuous variable cross-section technology is that there is no welding seam, the hardness change along the length direction is relatively gentle, it has better formability, and the surface quality is good, the production efficiency is high, and the cost is low. Luggage, medical equipment, motorcycle shell; automobile, bus inner roof, dashboard; seat backing, door panel, window frame, etc.

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for 2021 High quality Stainless Steel Cold Rolled Coil - Low Alloy Boiler Steel Plate – JINBAICHENG , The product will supply to all over the world, such as: Argentina, Canada, Anguilla, Our company regards "reasonable prices, high quality,efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!