2021 Good Quality Alloy Round Steel – Galvanized Flat Steel – JINBAICHENG

2021 Good Quality Alloy Round Steel – Galvanized Flat Steel – JINBAICHENG Detail:

Product Introduction

Standards: Ace, ASTM, bs, DIN, GB, JIS

Level: 304

Place of Origin: Shandong, China

Brand Name: Jinbaicheng

Type: stainless steel, cold rolled steel plate

Technology: Hot Rolled/Cold Rolled

Surface treatment: sandblasting

Application: metal products

Width: customized

Length: customized

Tolerance: ±1%

Processing services: welding, cutting, punching, cutting

Delivery time: 7-20 days

Technology: hot rolled and cold rolled

Shape: flat

Features: smooth surface

Surface: black or galvanized

Usage 1: Machinery manufacturing

Usage 2: Nuclear power

Usage 3: Food machinery

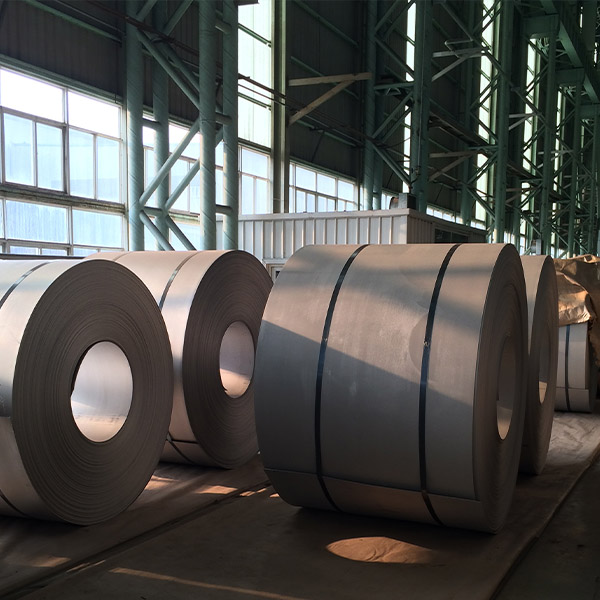

Product Display

main products

Section steel is one of the four major types of steel (plate, tube, profile, wire). According to the section shape, section steel is divided into simple section section steel and complex section section steel (section steel). The former refers to square steel, round steel, flat steel, angle steel, hexagonal steel, etc.; the latter refers to I-beam, channel steel, steel rail, window frame steel, curved steel, etc.

The main purpose

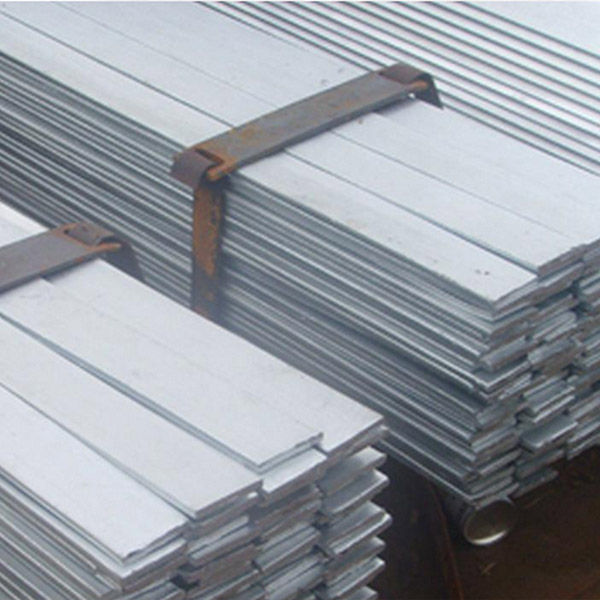

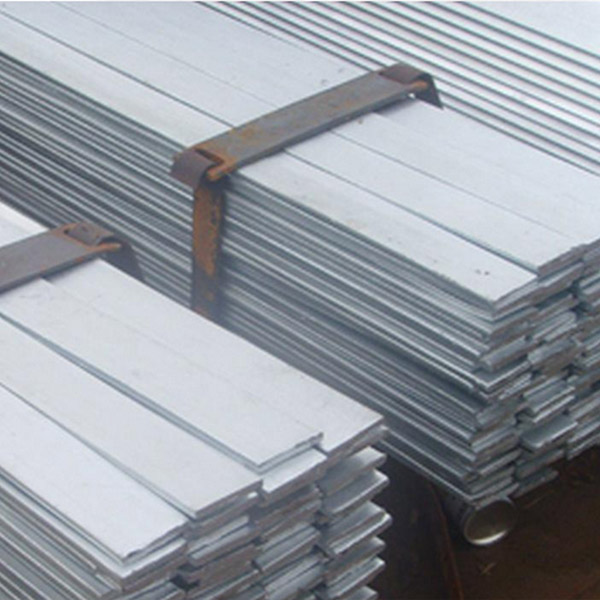

Galvanized flat steel can be used to make hoop irons, tools and mechanical parts as a finished material, and used as house frame structural parts and escalators in construction.

Galvanizing process

Hot-dip galvanizing is also called hot-dip galvanizing and hot-dip galvanizing: it is an effective metal anti-corrosion method, mainly used in metal structure facilities in various industries. The rust-removed steel parts are immersed in a molten zinc solution at about 500°C, so that a zinc layer is attached to the surface of the steel parts, thereby achieving the purpose of anti-corrosion.

Hot-dip galvanizing process: finished product pickling-water washing-adding auxiliary plating solution-drying-rack plating-cooling-medication-cleaning-polishing-hot-dip galvanizing completion

Hot-dip galvanizing is developed from the older hot-dip method. It has a history of 140 years since France applied hot-dip galvanizing to industry in 1836. However, the hot-dip galvanizing industry has been developed on a large scale with the rapid development of cold-rolled strip steel in the past 30 years.

Advantages of galvanized flat steel

1. The product specifications are special. The thickness is 8-50mm, the width is 150-625mm, the length is 5-15m, and the product specifications are relatively dense, which can meet the needs of users. It can be used instead of the middle plate and can be directly welded without cutting.

2. The surface of the product is smooth and clean. The high-pressure water descaling process is used twice in the process to ensure the surface of the steel is smooth and clean.

3. The sides are vertical and the water chestnuts are clear. The second vertical rolling in the finishing rolling ensures good verticality on both sides, clear corners, and good surface quality on the sides.

4. The scale of the product is accurate, three-point difference, the same level difference is better than the steel plate standard; the product is straight and the plate shape is good. The finishing rolling adopts the continuous rolling process, automatic looper automatic control, to ensure that no steel is piled or stretched, the product dimensional accuracy is high, the tolerance range, three-point difference, same line difference, sickle bend and other parameters are better than the medium plate, and the plate shape is straight. Degree is good. Cold shearing, high precision of length sizing.

5. The product material adopts national standards, which are the same as steel plates. The quality and technical standards are organized according to YB/T4212-2010 standards (Q345B/Q235B refer to GB/T1591-94 and GB/T700-88 standards respectively).

Product features

1. High strength, light structure: the firm grid pressure welding structure makes it have the characteristics of high bearing, light structure and easy hoisting;

2. Beautiful appearance and durability.

Product description

|

Thing |

Value |

|

Standard |

Astm, bs, din, gb, jis |

|

Grade |

Q235/q195/a36/ss400/s235jr |

|

Birthplace |

China |

|

Brand |

Tae young |

|

Technology |

Hot rolled/slitting/rounding |

|

Application |

Put up |

|

Width |

Custom made |

|

Length |

Custom made |

|

Tolerant |

±1% |

|

Type |

Stainless steel |

|

Processing service |

Welding, cutting, punching, other |

|

Delivery time |

7-20 days |

|

Technology |

Hot rolled and cold rolled |

|

Colour |

Black or galvanized |

|

Shape |

Flat steel |

|

Feature |

Smooth surface |

|

Key words |

Mental steel plate |

|

Usage |

Metal/construction/chemicals/pressure vessel |

technological process

Precision flat steel production process The working principle of the flat steel finishing machine is to use two sets of staggered up and down leveling wheels to pre-level and final level the thickness direction of cold flat steel wool; use a pair of oppositely arranged finishing The wheels are squeezed in the width direction so that the width is compressed to achieve the expected parameters, and the compression amount is adjustable; use 5 staggered straightening wheels to straighten the width. This system is mainly composed of a control box, a finishing roller, a pre-leveling unit, a finishing unit, and a straightening unit.

The production process can be summarized as: pre-leveling → finishing → straightening → post-leveling. Flat steel/a/b is a steel with a width of 12-300mm, a thickness of 4-60mm, a rectangular cross-section and slightly pure edges. Flat steel can be a finished steel product, or it can be used as a billet for welded pipes and thin slabs for stacked sheets. Main application: Flat steel can be used for making hoop iron, tools and mechanical parts as a finished material, and used as building frame structure and escalator in construction. Flat steel is divided into two types according to its shape: flat spring flat steel and single-sided double groove spring flat steel. Hot-rolled spring flat steel is mainly used to manufacture leaf springs for automobiles, tractors, railway transportation and other machinery.

Process method of spring flat steel for automobile

The spring flat steel is made by converter smelting process. Compared with the existing technology, it has the following advantages and positive effects:

1. Flat steel smelting in a converter mainly uses molten iron as raw material, which has fewer harmful elements in the molten iron, and the quality of the produced flat steel is guaranteed.

2. Due to the high yield and low power consumption, the cost per ton is lower than that of electric furnaces.

3. The molten steel is directly cast into billets, which eliminates the billeting process and reduces the cost.

4. The continuous casting billet has a high cut-to-length rate, which can guarantee the flat-steel cut-to-length rate and meet the needs of users.

Product detail pictures:

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for 2021 Good Quality Alloy Round Steel – Galvanized Flat Steel – JINBAICHENG , The product will supply to all over the world, such as: Panama, Muscat, Paraguay, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!